0.5-20 t/h MSW Sorting Plant A Key Link in Waste Resource Utilization

In the municipal solid waste treatment system, the 0.5-20 t/h MSW Sorting Plant is the core equipment for achieving waste reduction, resource utilization, and harmless treatment. It can accurately separate recyclable materials (such as plastics, metals, and paper), perishable waste, and other waste from municipal solid waste. It is suitable for different scenarios such as small community waste stations, medium-sized sanitation treatment points, and large waste transfer centers, providing efficient support for subsequent waste recycling and final disposal.

Sorting Plastic Bottles

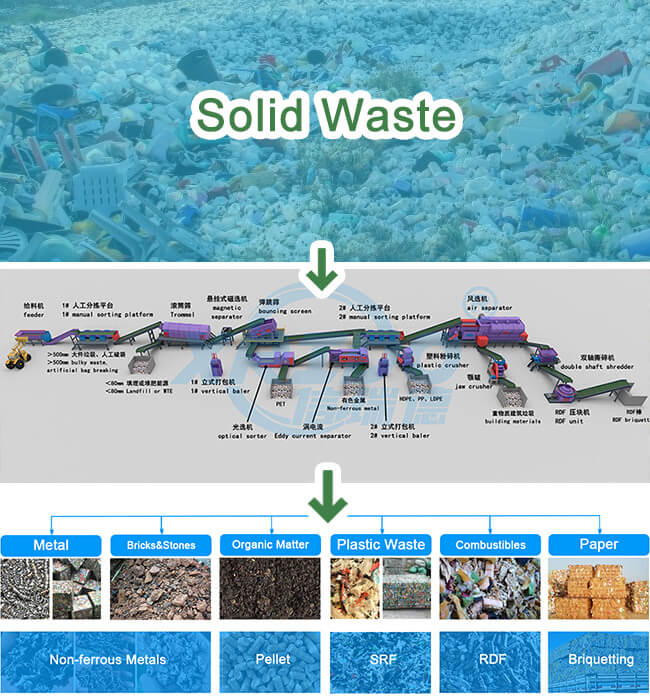

Sorting Solid Waste

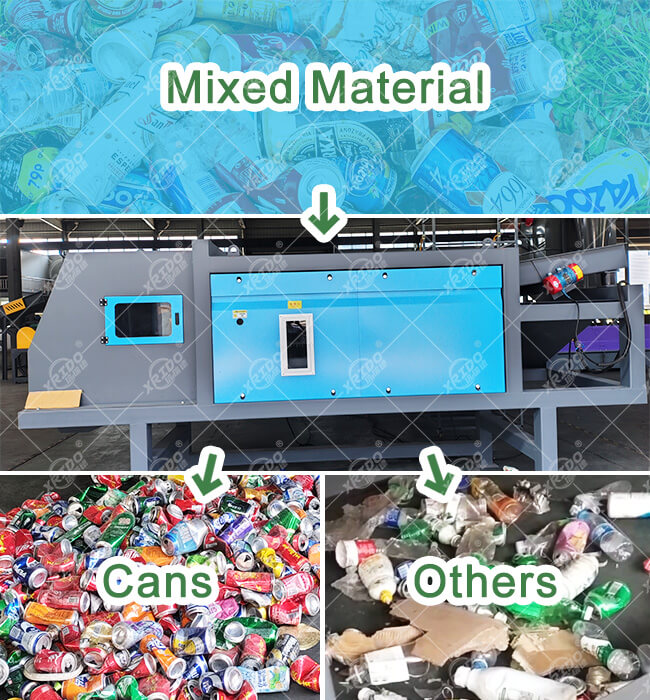

Sorting Mixed Material

Based on the complex composition and diverse forms of waste, this equipment adopts a combined system design of "pretreatment + multi-stage sorting". The pre-treatment stage removes large impurities (such as bricks, stones, and branches) using a drum screen, followed by a bag-breaking machine to open the garbage bags. The core sorting stage incorporates multiple sorting technologies: a magnetic separator separates scrap iron and steel, achieving a recovery rate of over 98%; an air separation system uses density differences to separate lightweight recyclables such as plastics and paper; and a bouncing screen precisely separates perishable waste from other waste based on its elasticity. The equipment's processing capacity ranges from 0.5 to 20 tons per hour, and can be adapted to different scales of waste processing needs by adjusting parameters such as drum speed and blower power.

MSW to RDF briquette Plant

Industrial Waste to SRF Plant

Biomass pellet/briquette Plant

Waste Tire Disposal System

In terms of performance, the equipment emphasizes stability and sorting accuracy. The machine body is made of corrosion-resistant steel, resisting corrosive substances in the waste and extending its service life. It is equipped with an intelligent monitoring system that monitors the operating status of each stage in real time. In case of blockages or overload, it automatically alarms and shuts down, reducing the risk of failure. Simultaneously, the equipment boasts high sorting accuracy, achieving a purity of over 85% for perishable waste and over 90% for recyclables, effectively reducing subsequent disposal costs.

From an environmental and economic perspective, this equipment can increase the recycling rate of municipal solid waste to 30%-40%, significantly reducing landfill and incineration volumes and lowering the risks of land occupation and air pollution. The separated perishable waste can be used to produce organic fertilizer, while recyclable materials such as plastics and metals can re-enter the industrial chain, generating economic benefits. Furthermore, the equipment has low energy consumption, consuming only 5-8 kWh per ton of waste processed, balancing environmental protection and economic efficiency.

Regarding operation and maintenance, the equipment uses a PLC automated control system with a touchscreen interface. Workers can become proficient in operation after 1-2 days of training, reducing labor costs. Routine maintenance is convenient; key components (such as magnetic separators and screens) can be quickly disassembled and replaced, and only periodic cleaning of residual waste inside the equipment is required, ensuring continuous and stable operation.