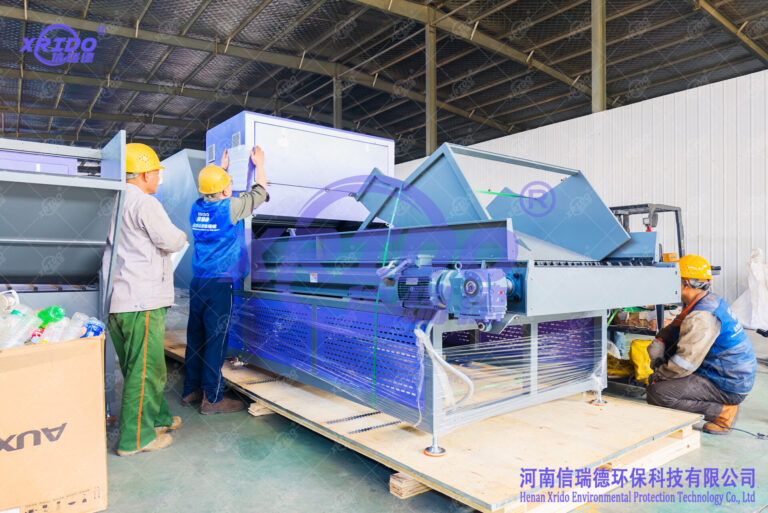

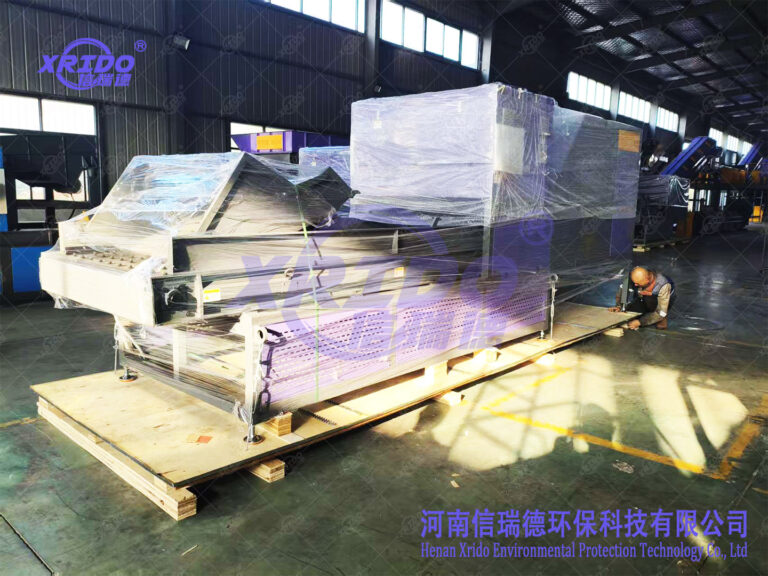

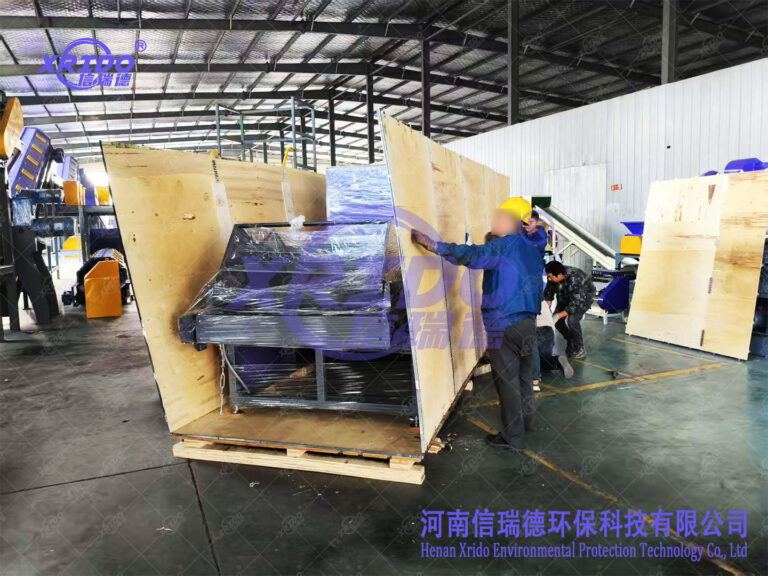

Three optical sorters were dispatched to Mexico to support the construction of a complete waste resource recovery system.

In 2026, Mexico City's "Transforming the City: Putting Waste Back in Place" law officially came into effect, mandating that residents separate their waste into three categories: organic, recyclable, and non-recyclable. However, the current correct waste separation rate in the area is only 15%, posing a dual challenge to the waste management system: accurate sorting and resource recovery upgrades. Against this backdrop, three high-performance optical sorters from XRIDO Machine were successfully shipped to Mexico, along with supporting waste sorting machines, crushers, complete recycling lines, and RDF (Recycling Distribution Filter) equipment. This comprehensive solution responds to the local "Circular City" strategy, making the "XRIDO Machine" brand a core contributor to the upgrading of waste management in Latin America.

optical sorters

optical sorters

optical sorters

The core pain point of Mexico's waste management lies in the insufficient accuracy of mixed material sorting, leading to the loss of recyclable resources and a surge in landfill pressure—Mexico City generates 8,500 tons of waste daily, of which 7,000 tons end up in landfills, and 21% of recyclables are not effectively utilized. XRIDO Machine's newly delivered optical sorter perfectly solves this problem: Equipped with a near-infrared spectral sensor and AI image recognition system, the device captures 300 frames of material images per second using a high-speed camera. Combined with a built-in database of over 200 materials, it can accurately identify materials such as PET, HDPE, glass, and aluminum within 0.1 seconds, achieving a sorting accuracy of over 99%. For difficult-to-sort materials such as flexible plastic packaging commonly found in Mexico, the device can flexibly adjust its recognition algorithm to perfectly adapt to the characteristics of local waste composition. It can process thousands to tens of thousands of items per hour, increasing efficiency by more than four times compared to traditional manual sorting.

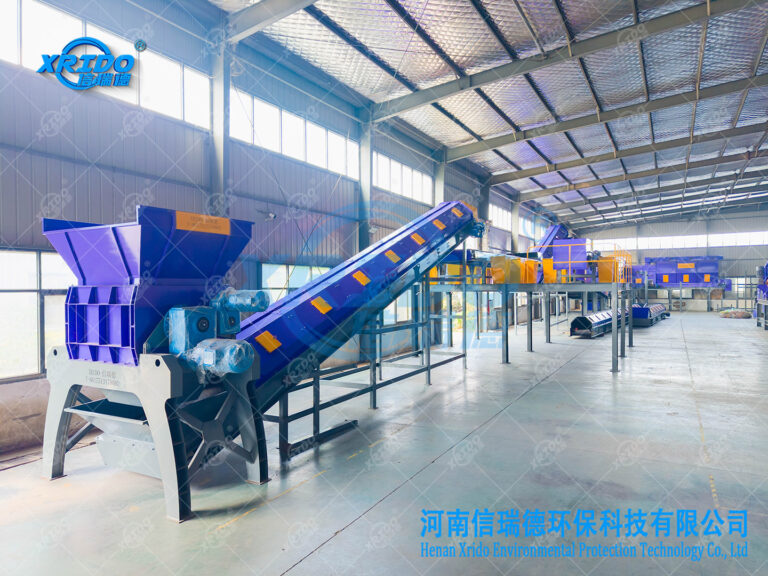

The effectiveness of a single optical sorter needs to be maximized through a complete system. XRIDO Machine's end-to-end "pre-processing - sorting - recycling" solution for its Mexican clients deeply integrates three optical separators with a municipal solid waste sorting machine, a crusher, a recycling line, and an RDF (Recycling Distribution Module) system. First, the crusher performs primary crushing of large mixed waste pieces to achieve uniform feeding standards. Then, the municipal solid waste sorting machine uses magnetic and air separation for pre-processing, separating metals and lightweight materials to reduce the sorting load on the optical separators. The optical separators then focus on fine sorting, accurately classifying recyclables such as plastics, paper, and glass according to their material composition, increasing purity to over 92%. Finally, the fully automated recycling line packages the materials, directly connecting them to downstream recycling processes.

MSW disposal plant

MBT plant

For non-combustible waste that cannot be directly recycled after sorting, XRIDO's RDF system achieves a significant value leap by "turning waste into energy." This equipment processes sanitary waste, polluted plastics, and other materials into high-calorie fuel pellets, which can directly replace fossil fuels in Mexico's newly built RDF power plant. This not only reduces landfill volume but also lowers industrial energy costs, echoing Yucatan State's environmental goal of reducing CO₂ emissions by 42,000 tons annually. This "sorting and recycling + energy utilization" model precisely aligns with Mexico City's zero-waste strategy of "50% landfill diversion."

MRF plant

Waste sorting and recycling plant. Equipment for automatic waste sorting.

As a brand deeply rooted in the environmental equipment field, XRIDO Machine's products are internationally certified and can be customized to meet different regional regulations. Specifically, for Mexico's new waste separation regulations, the equipment's material diversion channel has been optimized to ensure strict separation of organic, recyclable, and non-recyclable materials, meeting local sorting and collection requirements. The delivery of three optical separators and supporting equipment is not only a significant milestone for XRIDO Machine in expanding its Latin American market but also demonstrates its technological strength in supporting Mexico's circular economy development.

baler Machine

Magnetic Separation Machine

Pre-shredder

Textile RDF Production Line

In the future, XRIDO Machine will continue to upgrade the AI recognition algorithm and energy consumption control technology of its light separators, deepen the system synergy with municipal solid waste sorting machines and RDF equipment, provide more countries and regions with precise and suitable waste treatment solutions, and make "XRIDO Machine" a benchmark brand in the global waste resource utilization field.