The Difference Between Clean and Dirty Material Recycling Facilities: Xrido Group Customizes Equipment to Meet Diverse Needs

In resource recycling systems, Material Recycling Facilities (MRFs) can be categorized into clean material recycling facilities and dirty material recycling facilities based on the "cleanliness" of the materials they process. These two types differ significantly in their processing targets, process design, and equipment requirements. Xrido Group, leveraging its deep understanding of different scenarios, provides customized equipment solutions for both types of facilities, ensuring both recycling efficiency and environmental compliance are achieved.

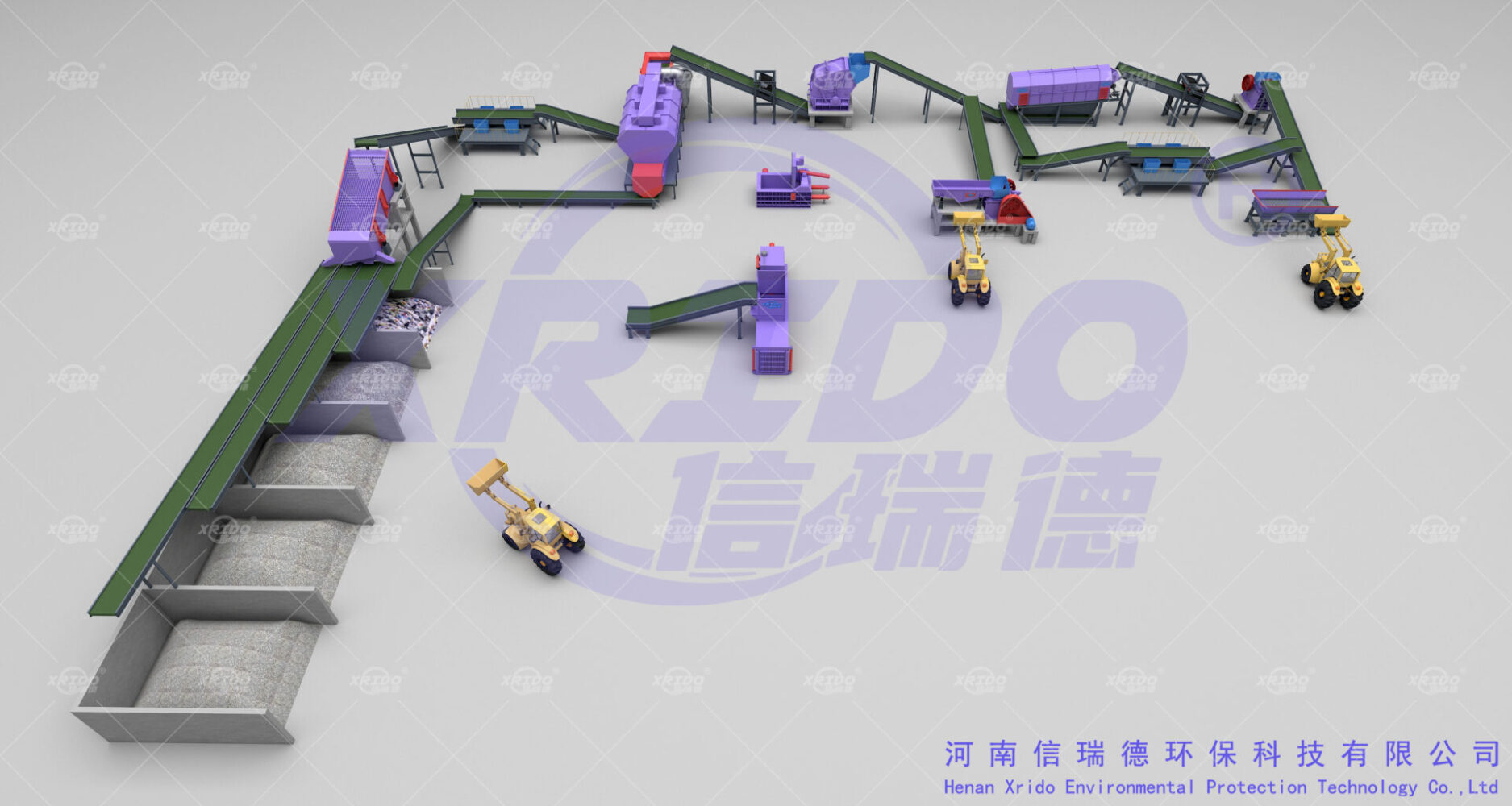

MRF

Waste sorting and recycling plant. Equipment for automatic waste sorting.

From the perspective of material characteristics, clean material recycling facilities primarily receive "pre-treated clean waste." This type of material often comes from the dedicated collection of recyclables from commercial premises and manufacturing enterprises, such as uncontaminated waste cardboard boxes, plastic packaging, and metal scraps. The materials themselves have few impurities and a simple composition, requiring no complex pre-treatment processes; the core requirement is "efficient sorting and packaging." Dirty material recycling facilities primarily handle mixed municipal solid waste and industrial solid waste. These materials contain impurities such as kitchen waste, oil, and silt, and may even contain harmful pollutants (e.g., battery residues and chemical residues). They require multi-stage pretreatment to remove impurities before sorting. The core requirement is "impurity separation and harmless treatment."

The differences between the two types of recycling facilities are more pronounced in their core process design. Clean material recycling facilities have a relatively simple process, typically involving "receiving - manual initial inspection - mechanical sorting - baling and output," requiring no complex washing or crushing pretreatment. Xrido Group equips these facilities with lightweight sorting equipment, such as intelligent belt sorters and high-speed balers, enabling rapid material flow with a processing capacity of 50-100 tons per hour and low energy consumption. Dirty material recycling facilities require a complex process of "multiple pretreatment + fine sorting": first, large impurities and silt are removed using Xrido Group's heavy-duty shredders and vibrating screens; then, recyclable materials are separated using magnetic separation, air separation, and eddy current separation equipment; finally, non-recyclable waste is compressed. Some scenarios also require Xrido Group's environmentally friendly cleaning equipment to remove surface oil and ensure the purity of recycled materials.

Pre-shredder

Pre-shredder

Regarding equipment requirements, the two types of facilities have significantly different needs for equipment durability and corrosion resistance. Clean material recycling facilities do not require equipment to cope with high-pollution, high-abrasion environments; Xrido Group's standardized sorting equipment is sufficient, focusing on optimizing efficiency and cost. Dirty material recycling facilities, on the other hand, require equipment with strong corrosion and wear resistance. Xrido Group's customized waste sorting machines and crushing equipment for these facilities use anti-corrosion coatings and high-hardness alloy components to resist the erosion of oil and chemical residues. They are also equipped with sealed chambers and exhaust gas treatment systems to prevent pollutant leakage and meet environmental standards.

trommel screen

optical sorter

Whether it's a cleaning or waste material recycling facility, the core goal is to achieve efficient resource recycling. Xrido Group provides differentiated equipment solutions by accurately grasping the needs of both types of facilities. This enables cleaning material recycling facilities to achieve "efficient circulation" while allowing waste material recycling facilities to overcome the bottleneck of "impurity treatment," empowering material recycling facilities in different scenarios and promoting the comprehensive coverage of the resource recycling system.