How Do Material Recycling Facilities Operate? Xrido Group's Waste Disposal Machines Enable Efficient Flow

Material recycling facilities (MRFs), as the core hub of waste resource utilization, operate around the process of "sorting, purification, conversion, and recycling." Through specialized equipment and a systematic division of labor, mixed waste is transformed from "garbage" into recyclable raw materials. The waste disposal machine is the key equipment throughout the entire process, and Xrido Group, with its customized equipment solutions, makes the operation of material recycling facilities more efficient and precise, promoting the implementation of resource recycling.

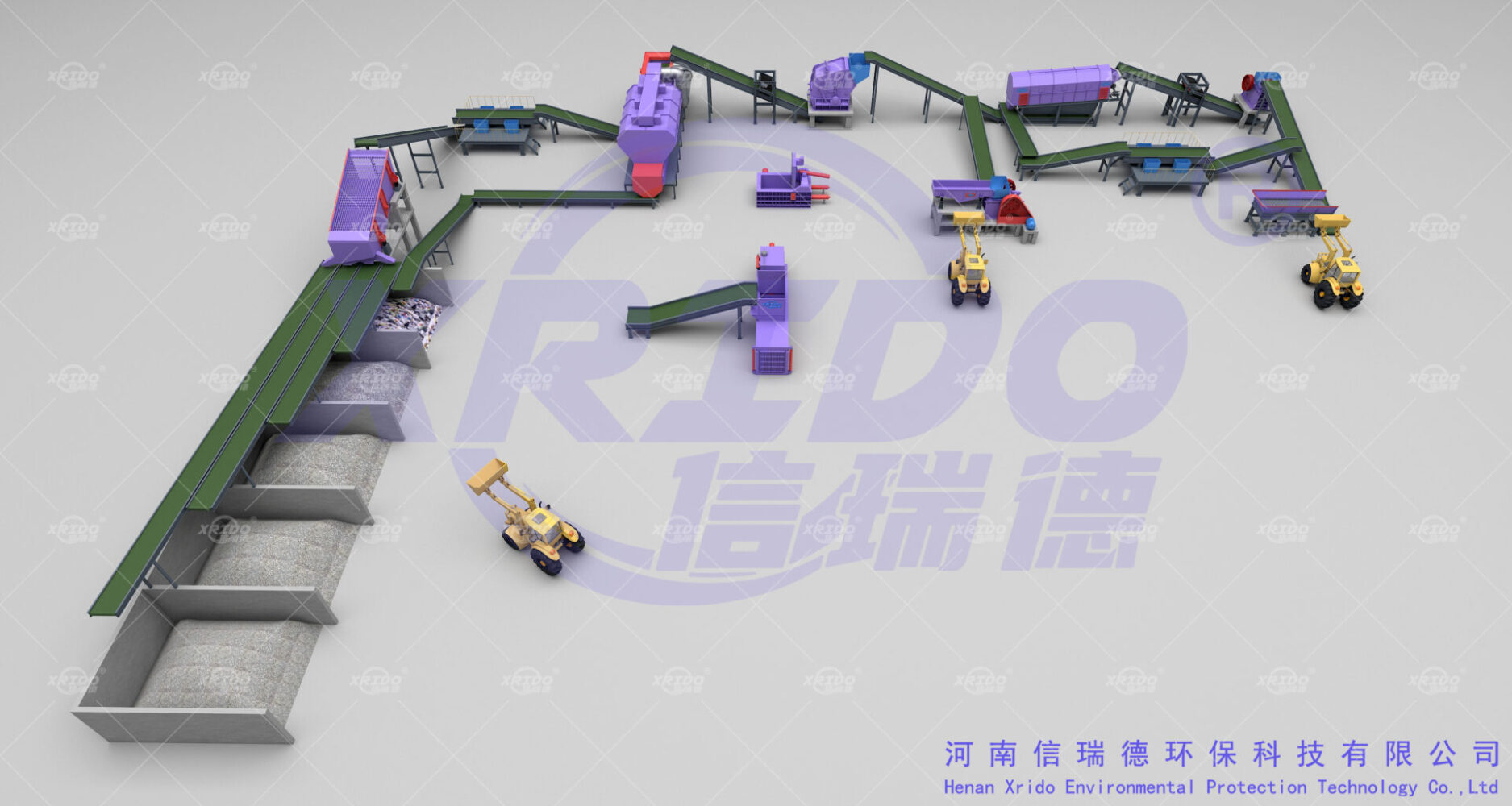

MRF

MRF plant

The operation of a material recycling facility can be divided into four core stages, each relying on the support of the waste disposal machine. The first step is "receiving and pre-processing": After mixed waste (household waste, industrial solid waste, etc.) arrives at the facility, it is first registered through a weighing system. Then, Xrido Group's primary waste disposal machine removes large impurities (such as furniture, bricks, and hard metal blocks), while simultaneously breaking up and initially screening the materials to prevent large objects from affecting subsequent processes, laying the foundation for refined processing.

The second step is "refined sorting," which is the core of the material recycling facility's operation. After pretreatment, the materials enter the Xrido Group intelligent waste disposal system: a magnetic separation module separates ferromagnetic metals (such as iron nails and scrap steel), an eddy current separation module extracts non-ferrous metals such as aluminum and copper, and an air separation and screening module separates plastics, paper, kitchen waste, and other components based on material density and particle size. The entire disposal system is automated, achieving a sorting accuracy of over 95%, avoiding the inefficiency and errors of manual sorting and ensuring precise separation of various recyclable materials.

Air Separator

Magnetic Separation Machine

optical sorter

trommel screen

The third step is "crushing and compression": For large pieces of recyclable material after sorting (such as plastic buckets and waste paper bags), Xrido Group's specialized waste disposal machine plays a crucial role. Pre shredder has low-speed, high-torque crushing structure breaks the material into uniform small pieces, reducing volume, lowering transportation costs, and facilitating downstream recycling. The crushed material is then compressed and packaged into standardized recyclable raw material packages, improving transportation and utilization efficiency. For non-recyclable hazardous waste, the disposal machine also performs closed-loop crushing and harmless pretreatment to prevent environmental pollution.

Pre-shredder

Pre-shredder

baler Machine

baler Machine

The fourth step is "resource recovery": Recycled materials processed by the waste disposal machine are then sorted and transported to downstream enterprises—metal raw materials are used for smelting and recycling, plastics and paper are reprocessed into new products, and organic waste is converted into biomass fuel through fermentation. The efficient operation of Xrido Group's waste disposal machines increases the resource recovery rate of material recycling facilities by 30% compared to traditional methods and shortens the processing cycle by 40%, truly realizing "turning waste into treasure."

From receiving materials to outputting recycled raw materials, the entire operation of material recycling facilities relies on the support of professional waste disposal machines. Xrido Group, with its highly adaptable, efficient, and environmentally compliant equipment solutions, has become a core partner for material recycling facilities, ensuring smooth and efficient operation while helping facilities achieve their goals of "reduction, harmlessness, and resource recovery," thus promoting the high-quality development of the environmental protection industry.