How does a Material Recycling Facility (MRF) work? Xrido Group equipment is integrated throughout the core process.

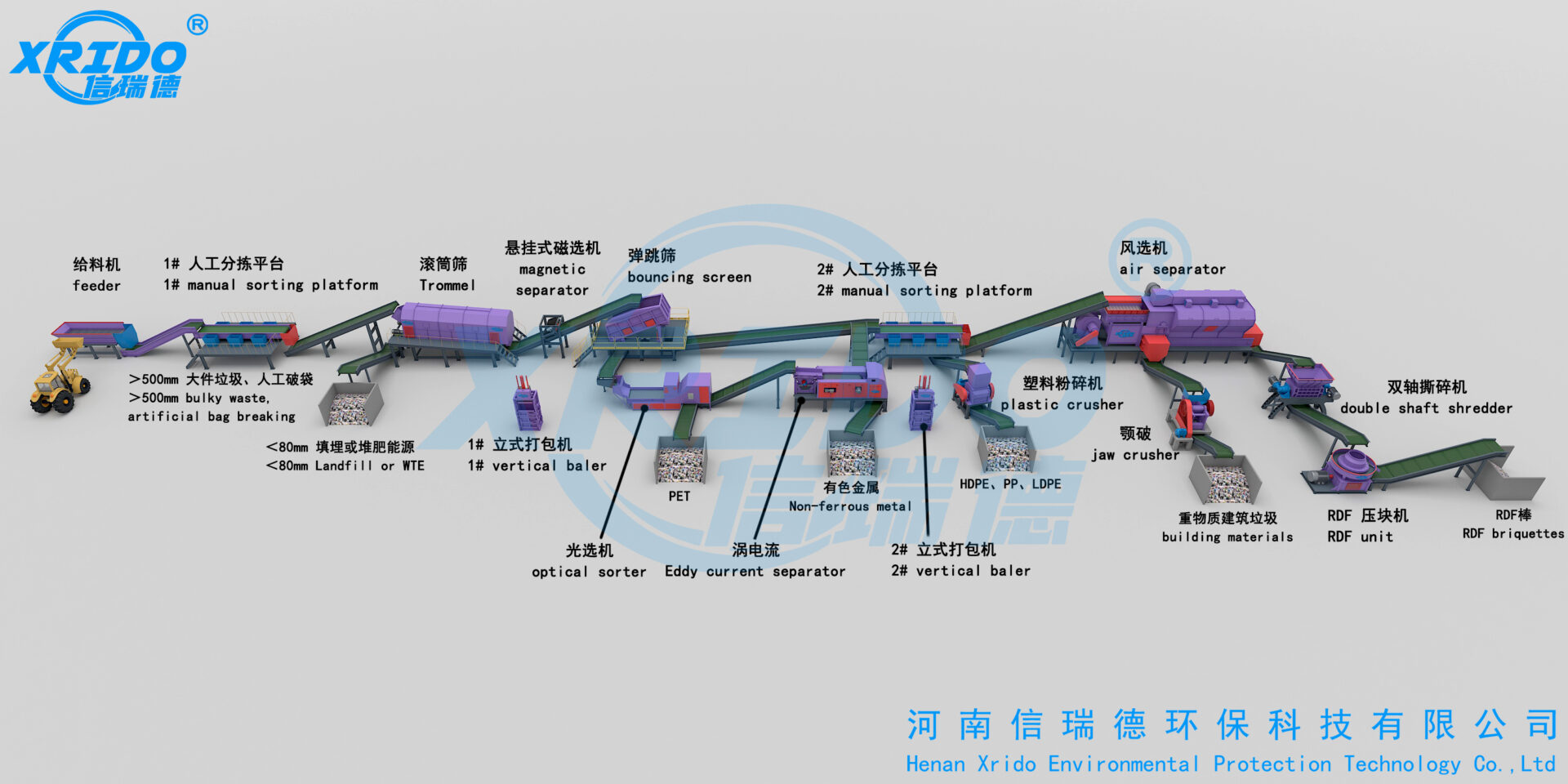

The working principle of a Material Recycling Facility (MRF) revolves around "extracting recyclable resources from mixed waste." Through a systematic process of "physical separation + mechanical processing," it achieves "classification - purification - resource recovery" of waste. As a professional equipment service provider, Xrido Group's customized sorting, crushing, and conveying equipment is integrated throughout the entire workflow, ensuring efficient operation at each stage and significantly improving the resource extraction rate and processing efficiency of the MRF.

materials recovery facilities

Waste sorting and recycling plant. Equipment for automatic waste sorting.

The first step in the MRF workflow is "material receiving and preliminary screening," which is fundamental to ensuring subsequent processing efficiency. After mixed waste (such as municipal solid waste and industrial solid waste) arrives at the facility by transport vehicles, its total weight is recorded by a weighing system before it enters Xrido Group's heavy-duty feeding conveyor. The device is equipped with a metal detection module, which can identify and remove large metal blocks (such as steel bars and scrap iron) from materials in advance to avoid damaging subsequent equipment. Simultaneously, manual screening removes excessively large impurities (such as furniture and bricks), ensuring that materials entering the next stage meet processing standards. The core principle of this step is "early obstacle removal to ensure a smooth process."

The second step is "pre-treatment crushing and homogenization." The waste shredder machine is to break up material agglomerates and reduce their volume through mechanical action, creating conditions for fine sorting. Materials that have undergone preliminary screening enter Xrido Group's low-speed, high-torque crusher. Its dual-shaft shearing structure can crush large mixed waste (such as plastic buckets and waste paper bags) into uniform particles of 5-10cm, avoiding the impact of material size differences on sorting accuracy and breaking up tangled waste (such as plastic bags and wires). For materials containing moisture or sticky impurities, the equipment can also be equipped with a simple dewatering module to reduce the interference of moisture on subsequent sorting, achieving a pre-treatment effect of "uniform particle size and preliminary impurity separation."

Pre-shredder

Pre-shredder

The third step is "multi-process collaborative sorting," which is the core of the material recycling facility's working principle and aims to accurately separate different types of recyclable resources. This step utilizes Xrido Group's specialized sorting equipment: a magnetic separator uses a magnetic field to attract ferromagnetic metals (such as nails and aluminum cans), based on the magnetic differences between materials; an eddy current separator generates an alternating magnetic field, causing non-ferrous metals (such as aluminum and copper) to generate induced currents and be separated by force, achieving comprehensive extraction of metallic resources; an air separator separates lightweight plastics and paper from heavy sediments and glass based on material density differences; finally, a vibrating screen further purifies recyclables by particle size. The entire sorting process operates on the principle of "utilizing the differences in material physical properties (magnetism, density, particle size) to achieve precise separation through specialized equipment." Xrido Group's equipment combination allows for a sorting purity of over 95%.

optical sorter

trommel screen

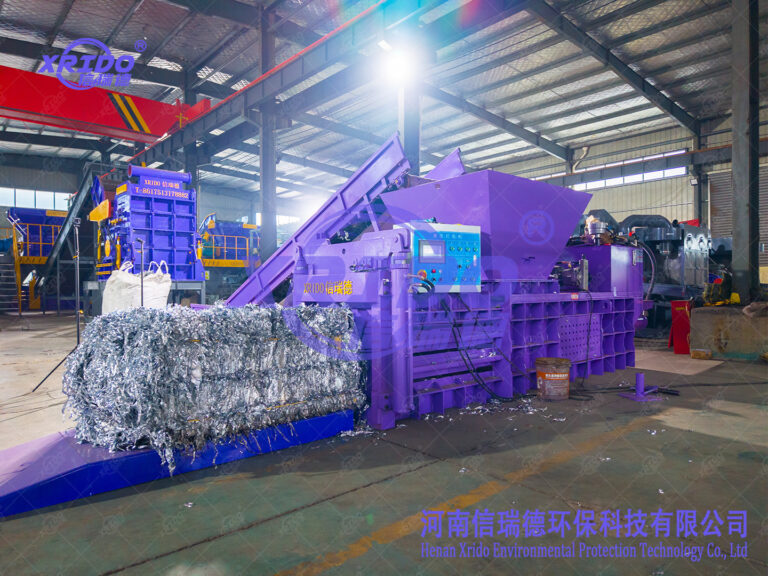

The fourth step is "resource packaging and waste treatment," completing the final separation of resources from waste. After sorting, recyclable materials (such as metal particles, plastic fragments, and paper fibers) enter Xrido Group's automated balers, where they are compressed into standardized bales for easy transport to downstream recycling companies. Non-recyclable waste is then transported to landfills or incinerators via a closed conveyor system for safe disposal. The principle behind this step is "classification and disposal, allowing recyclable resources to enter the recycling cycle, and standardizing the disposal of non-recyclable waste."

baler Machine

baler Machine

From material reception to final output, the working principle of material recycling facilities revolves around "physical separation and resource extraction." Xrido Group's equipment, adapted to the technical requirements of each stage, ensures the efficient implementation of this principle, improving resource recovery rates while guaranteeing the environmental friendliness and stability of the processing flow, thus becoming the core support for the efficient operation of material recycling facilities.