How to Improve the Efficiency of Material Recycling Facilities? Xrido Group's Technology Solutions Enable Upgrades

The efficiency of a Material Recycling Facility (MRF) directly determines the capacity and revenue of resource recycling. Improving efficiency requires breakthroughs across multiple dimensions, including equipment performance, process design, and intelligent management. Leveraging its deep understanding of material recycling scenarios, Xrido Group helps material recycling facilities overcome pain points such as slow sorting, low purity, and high energy consumption through customized equipment and systematic solutions, achieving comprehensive efficiency improvements.

High angle close-up of pieces of recyclable garbage on conveyor belt inside waste management facility.

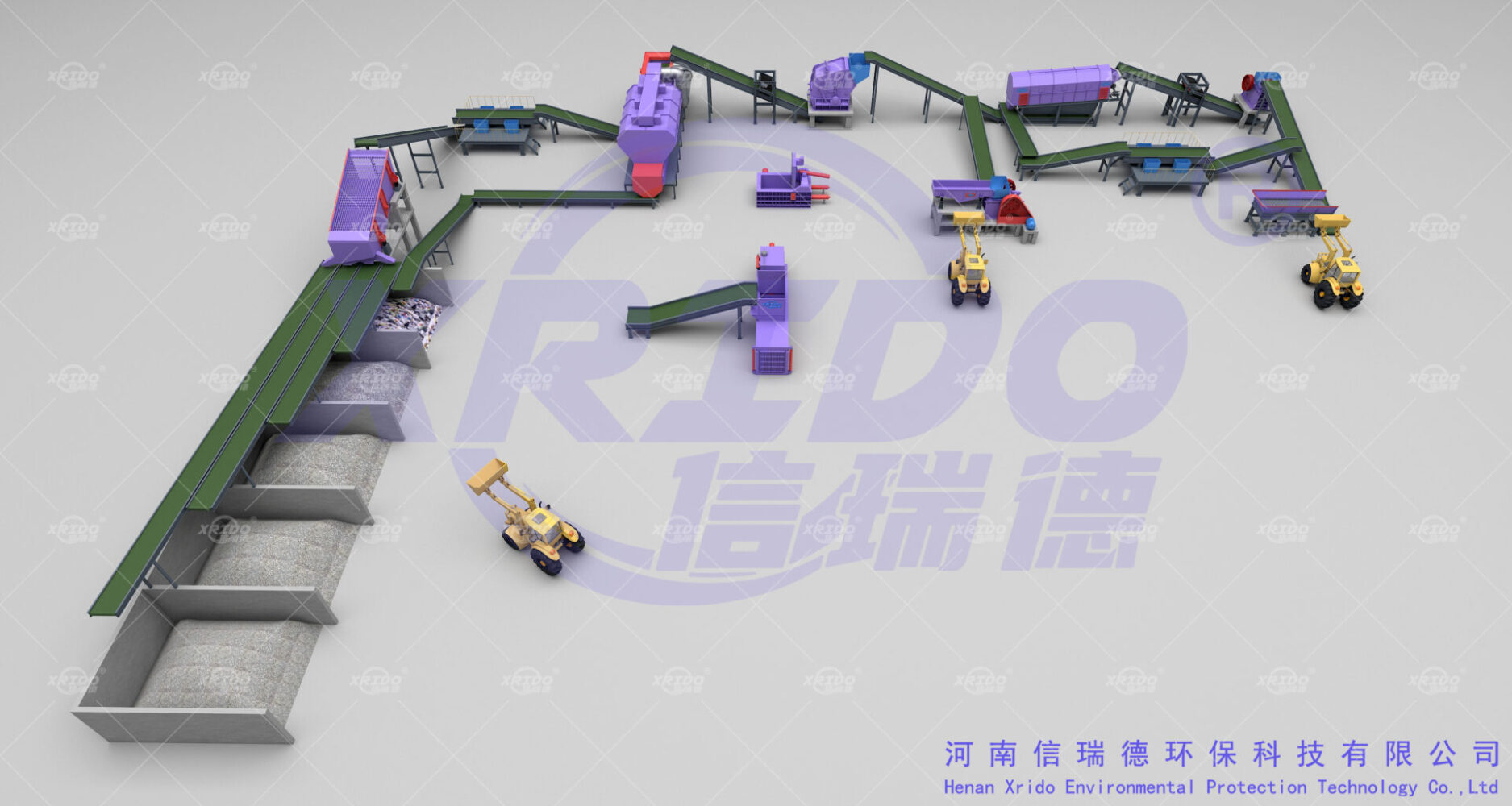

MRF plant

Upgrading core equipment is fundamental to improving the efficiency of material recycling facilities. In traditional facilities, the high proportion of manual sorting and low precision of mechanical sorting limit overall efficiency. To address this issue, Xrido Group has launched an integrated "intelligent sorting + high-efficiency crushing" equipment combination: its intelligent waste sorting machine integrates magnetic separation, air separation, and eddy current separation technologies, automatically identifying and separating different materials such as metals, plastics, and paper, with a sorting accuracy of over 95% and efficiency 8 times higher than manual processing. The accompanying low-speed, high-torque crushing equipment can quickly process large pieces of mixed waste, crushing materials to a uniform particle size, reducing subsequent sorting resistance, and increasing the facility's hourly processing capacity by 30%, effectively solving the problems of "material jamming and sorting delays."

Optimizing the processing flow is a key aspect of improving efficiency. Many material recycling facilities suffer from problems such as "long pre-processing times and material backlogs" due to inefficient process connections. Xrido Group provides modular process design for its facilities: based on material characteristics (clean/dirty, mixed/single), it plans a seamless path from "receiving - pre-processing - sorting - packaging"—for example, for mixed dirty waste, Xrido Group's vibrating screens first remove mud and impurities before it enters the sorting stage, preventing impurities from affecting sorting efficiency; simultaneously, an automated conveyor system enables rapid material flow between stages, reducing manual handling time and shortening the entire processing cycle by 40%, completely solving the "process breakpoint" problem.

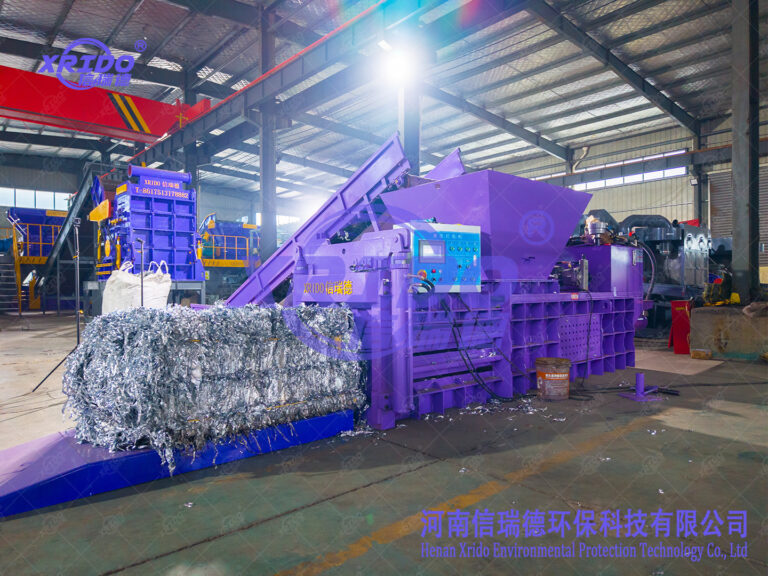

baler Machine

baler Machine

Introducing intelligent management technology can further unlock efficiency potential. Some material recycling facilities lack data monitoring, making it difficult to accurately adjust operational strategies. Xrido Group equips its facilities with an IoT monitoring system that can collect real-time equipment operation data (such as sorting efficiency, energy consumption, and fault warnings) and material recycling data (such as the recycling rate of various resources), generating optimization suggestions through background algorithms. For example, when the system detects a decline in metal sorting efficiency, it automatically prompts for calibration of the magnetic separation module parameters; it adjusts material receiving priorities based on recycling data, prioritizing the processing of high-value waste, thereby increasing facility resource returns by 25% and achieving "data-driven efficiency optimization."

Pre-shredder

Pre-shredder

Improving the efficiency of material recycling facilities requires a coordinated effort across "equipment, processes, and management," and Xrido Group provides comprehensive support for facilities from hardware to software through customized technical solutions. Whether it's upgrading core equipment, optimizing processes, or empowering intelligent management, Xrido Group can precisely match facility needs, helping them overcome efficiency bottlenecks, increasing capacity while reducing operating costs, and driving the upgrade of material recycling facilities towards "high efficiency, intelligence, and greenness."