Material Sorting and Recycling Processes for Mixed Waste: Xrido Group Sorting Machines Enable Efficient Resource Utilization

Mixed waste (such as household waste, industrial mixed waste, and commercial miscellaneous materials) has always been a challenge for resource recycling due to its complex composition (containing plastics, metals, paper, organic waste, etc.). A scientific mixed waste recycling process requires "precise sorting" to achieve resource separation. Xrido Group's professional mixed waste sorting machine, with its multi-technology collaborative design, has become a core piece of equipment for promoting process implementation and improving recycling efficiency, helping mixed waste transform from "garbage" into renewable resources.

The first step in the mixed waste recycling process is "pre-treatment and impurity removal," clearing obstacles for subsequent sorting. Mixed waste often contains large impurities (such as bricks and furniture fragments) and tangled materials (such as plastic bags and wires). If these directly enter the sorting stage, it can easily cause the equipment to stall. Xrido Group's mixed waste sorting machine is equipped with a "primary crushing + screening" pretreatment module: a low-speed shearing crusher can break large waste pieces down to within 50cm, preventing clogging; the vibrating screening module separates mud, sand, and fine impurities, while breaking up tangled clumps of material. After pretreatment, the "cleanliness" of the mixed waste is improved by 40%, laying the foundation for refined sorting and solving the pain point of "impurities interfering with sorting" in traditional processes.

Pre-shredder

Pre-shredder

"Multi-process collaborative sorting" is the core of mixed waste recycling technology and the key to resource extraction. This step requires precise separation based on the physical properties (magnetism, density, material properties) of different materials. Traditional manual sorting is inefficient, error-prone, and difficult to meet the needs of large-scale operations. Xrido Group's mixed waste sorting machine integrates four core technologies: a magnetic separation module uses magnetic fields to attract ferromagnetic metals (such as iron nails and scrap steel), achieving a sorting rate of over 98%; an eddy current separation module uses induced current to separate non-ferrous metals such as aluminum and copper, accurately extracting even tiny metals as small as 5mm in diameter; an air separation module separates lightweight plastics and paper from heavy materials based on density differences; and an AI vision sorting module uses high-definition cameras and algorithms to identify and separate materials of specific colors or textures (such as transparent PET plastic and colored PVC plastic). The entire system achieves fully automated sorting, increasing efficiency by 8 times compared to manual labor, and achieving a resource separation purity of 95% for mixed waste.

trommel screen

optical sorter

Magnetic Separation Machine

"Resource transformation" is the ultimate goal of mixed waste recycling processes, requiring the realization of value based on the characteristics of the sorted materials. Metals separated by Xrido Group's mixed waste sorting machine can be directly transported to smelters for recycling; plastics, paper, and other materials, after being crushed and packaged, become raw materials for downstream processing plants; and non-recyclable residual waste, due to its simple composition after sorting, can have its subsequent disposal costs reduced through volume reduction treatment. Data shows that mixed waste recycling lines equipped with this sorting machine achieve a 35% higher resource recovery rate than traditional processes, producing an additional 15-20 tons of recycled raw materials for every 100 tons of mixed waste processed, demonstrating significant economic and environmental benefits.

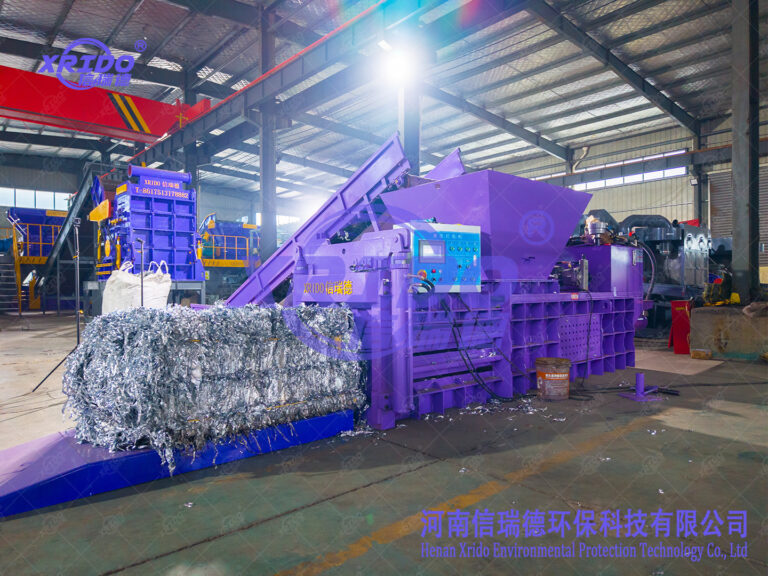

baler Machine

baler Machine

Furthermore, Xrido Group's mixed waste sorting machine boasts strong adaptability and environmental friendliness. The equipment can flexibly adjust sorting module parameters according to the type of mixed waste (municipal waste, industrial waste, commercial miscellaneous materials) to meet the needs of different scenarios; the fully enclosed design and negative pressure dust removal system effectively control dust and odors generated during the sorting process, meeting national environmental standards and preventing secondary pollution.

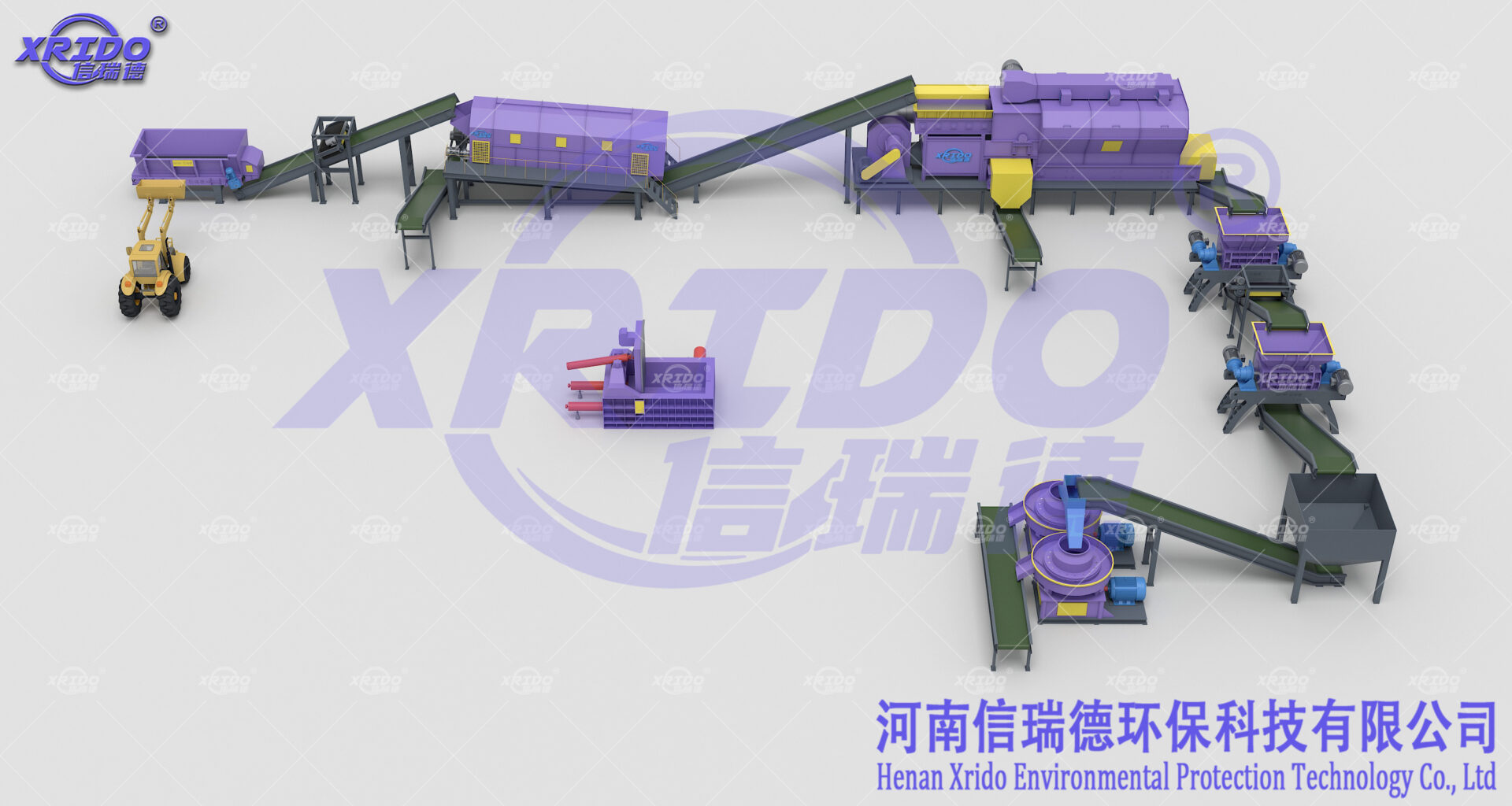

MRF plant

Waste sorting and recycling plant. Equipment for automatic waste sorting.

Municipal Solid Waste Processing Process, Xrido Machine

With the increasing urgency of resource recycling, the material sorting and recycling processes for mixed waste are upgrading towards "high efficiency and precision." With its advantages of "multi-technology synergy, high separation efficiency, and strong scenario adaptability," the Xrido Group's mixed waste sorting machine has become a key support for the implementation of processes. It can not only solve the problem of mixed waste recycling, but also promote the construction of a resource recycling system and help enterprises achieve a "win-win situation for environmental protection and economic benefits."