A municipal solid waste sorting system (MSW) is a system that efficiently separates and sorts different components (such as recyclables, organic matter, inert materials, and hazardous materials) within mixed waste (MSW) through mechanized, automated, or semi-automated equipment and processes.

It is one of the most core technical components of the municipal solid waste recycling system, aiming to improve waste resource utilization, reduce landfill and incineration volumes, promote the development of a circular economy, and provide high-quality raw materials for subsequent processes (such as recycling, composting, incineration, and RDF production).

- Why is waste sorting necessary?

In cases of mixed collection or incomplete front-end sorting, waste often enters the processing stage in a mixed state. The functions of the sorting system are:

✅ Separating valuable materials (such as recyclables like plastics, paper, metal, and glass) to improve resource recovery rates

✅ Removing impurities and harmful substances to protect subsequent processing equipment and the environment

✅ Providing suitable raw materials for different treatment processes (such as composting/anaerobic processing of food waste, and RDF/incineration of combustible materials)

✅ Improving waste treatment efficiency and economic benefits, promoting waste reduction, resource utilization, and harmlessness

II. Common waste treatment targets of municipal waste sorting systems:

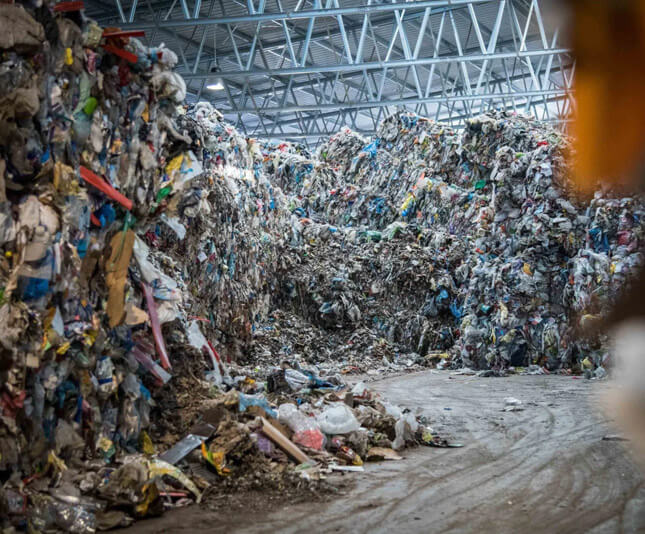

- Mixed household waste (unsorted or roughly sorted waste)

- Mixed food waste and other waste streams

- Mixed recyclables and other impurities

- Large garbage after disassembly, garden garbage, commercial garbage, etc.

III. Core objectives of municipal waste sorting system

Recyclables: paper, plastic, metal, glass, etc., for recycling and reuse

Organic matter: kitchen waste, food scraps, etc., for composting, anaerobic fermentation or biological treatment

Inert matter: stone, ceramics, glass fragments, dust, usually landfilled or used as building materials

High calorific value: combustibles such as plastic, paper, fiber, used to make RDF (refuse-derived fuel)

Hazardous materials: batteries, light bulbs, medicines, etc., which need to be safely diverted and specially handled

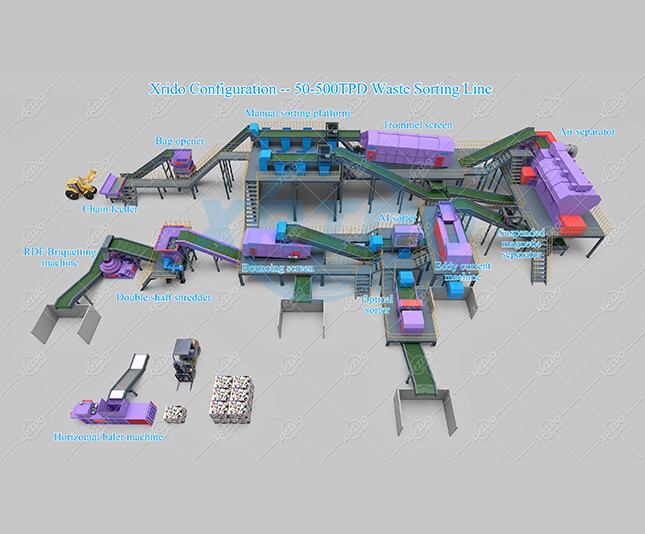

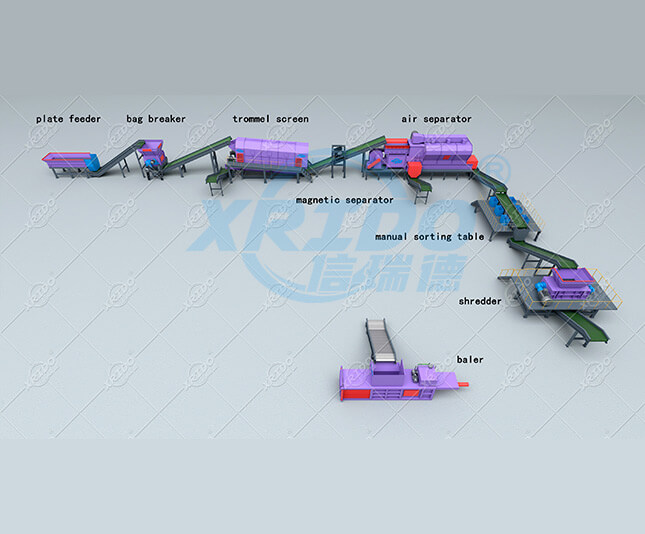

IV. Main process flow and equipment of municipal waste sorting system

- Pretreatment stage

(1) Bag opener

- Function: Break the garbage in the plastic bag to release the internal materials for subsequent sorting

- Equipment: Rotary knife bag opener, vibrating bag opener, etc.

(2) Screening (Screening machine / Trommel Screen) - Function: Preliminary separation according to material size

- Large size (>80/100mm): Cardboard, plastic bags, and large miscellaneous items

- Medium size (20-80mm): Mixed combustibles, small plastics

- Small size (<20mm): Fine inorganic matter, sand, and food waste

- Commonly used equipment: Trommel screen, vibrating screen

- Air Classification

- Function: Separates light materials (such as plastics and paper) from heavy materials (such as metals, glass, and stone) by utilizing differences in density and suspension velocity.

- Commonly used equipment: Positive/negative pressure air separators, eddy current air separators

- Typical separation results:

- Light components: Plastic bags, films, paper, and fibers → Combustibles/RDF feedstock

- Heavy components: Metals, glass, stone, and food waste → Inerts or further separation

- Magnetic Separation

- Purpose: Removes or recycles ferromagnetic metals (such as cans, wire, nails, etc.) from waste.

- Equipment: Suspension magnetic separator, belt magnetic separator, permanent magnet drum

- Results: Recovers ferrous metals, improves resource utilization, and protects subsequent equipment.

- Eddy Current Separation (ECS)

- Purpose: Separates non-ferrous metals (such as aluminum and copper). A high-speed rotating magnetic field is used to induce eddy currents in non-ferrous metals, which are then ejected.

- Applicable to: Aluminum foil, cans, copper wire, etc. in mixed plastics.

- Equipment: Eddy current separator (usually located after air separation or bouncing screens).

- Near Infrared Sorting (NIR) / Optical Sorting

- Purpose: Accurately identifies and separates different types of plastics, paper, fabric, etc. by identifying the spectral characteristics of the materials.

- Examples of materials that can be sorted:

- PET bottles, HDPE bottles

- PS foam, PVC

- Mixed paper and plastics

- Equipment: Near-infrared sorting machine, vision recognition + air jet rejection system (AI image recognition)

✅ High-end sorting lines often use a combination of NIR + AI vision + robotic sorting to achieve high-precision sorting.

- Density Sorting / Gravity Sorting / Ballistic Screening

- Function: Further separates materials such as plastics, rubber, and organic matter based on their bouncing characteristics or specific gravity.

- Equipment: Ballistic Separator, Gravity Sorting Machine

- Manual Sorting (Assisted)

- Some sorting lines still have a manual sorting platform to handle complex materials, materials with high levels of foreign matter, or materials difficult for machines to identify.

- Usually located at the front end or key nodes of the sorting line.

Waste Sorting Machine

V. Typical Municipal Waste Sorting System Flowchart (Simplified)

Mixed Domestic Waste

↓

[Pretreatment]

├─ Bag Breaker (Unpacking)

↓

[Screening] (Drum Screen / Vibrating Screen)

├─ Large Size (Hard Objects, Plastics, Paper)

├─ Medium size (mixed combustibles)

└─ Small size (fine inorganic matter, sand)

↓

[Wind separation]

├─ Light fraction (plastics, paper, fibers → combustibles/RDF)

└─ Heavy fraction (metals, glass, rocks, etc.)

↓

[Magnetic separation] → Recover ferrous metals

↓

[Eddy current separation] → Recover non-ferrous metals such as aluminum and copper

↓

[Near-infrared/optical separation] → Finely separate plastic and paper types

↓

[Bounce screen/density separation] → Further separate organic matter/inerts

↓

[Manual sorting (optional)]

↓

→ Different material flows: recycling, composting, RDF, incineration, landfill, etc.