Working principle

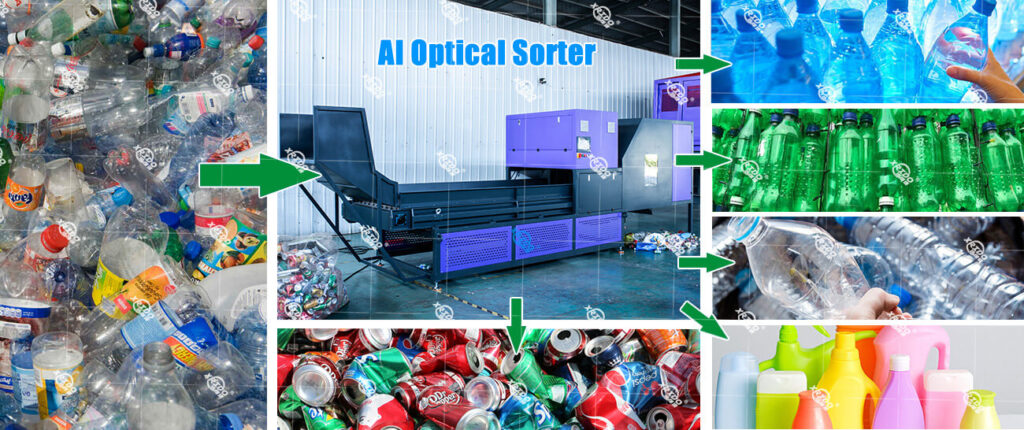

Optical sorter, also known as photometric sorter, is a device that uses the different light reflection characteristics of materials for sorting. It combines modern detection, sensing, artificial intelligence and other technologies to quickly identify the physical characteristics of materials and separate materials from waste.

Working principle of optical sorter:

Optical sorter mainly uses ultraviolet light, visible light, infrared light and other objects to produce absorption, reflection and transmission phenomena to detect materials. Then, compressed air, water or robotic arms are used to separate target materials from non-target materials.

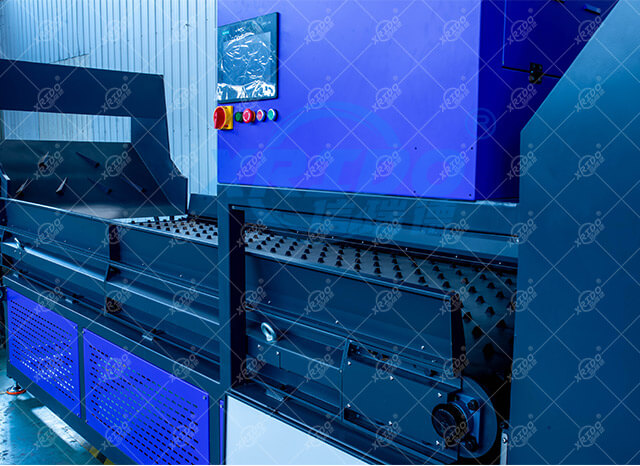

Optical Sortting Machine

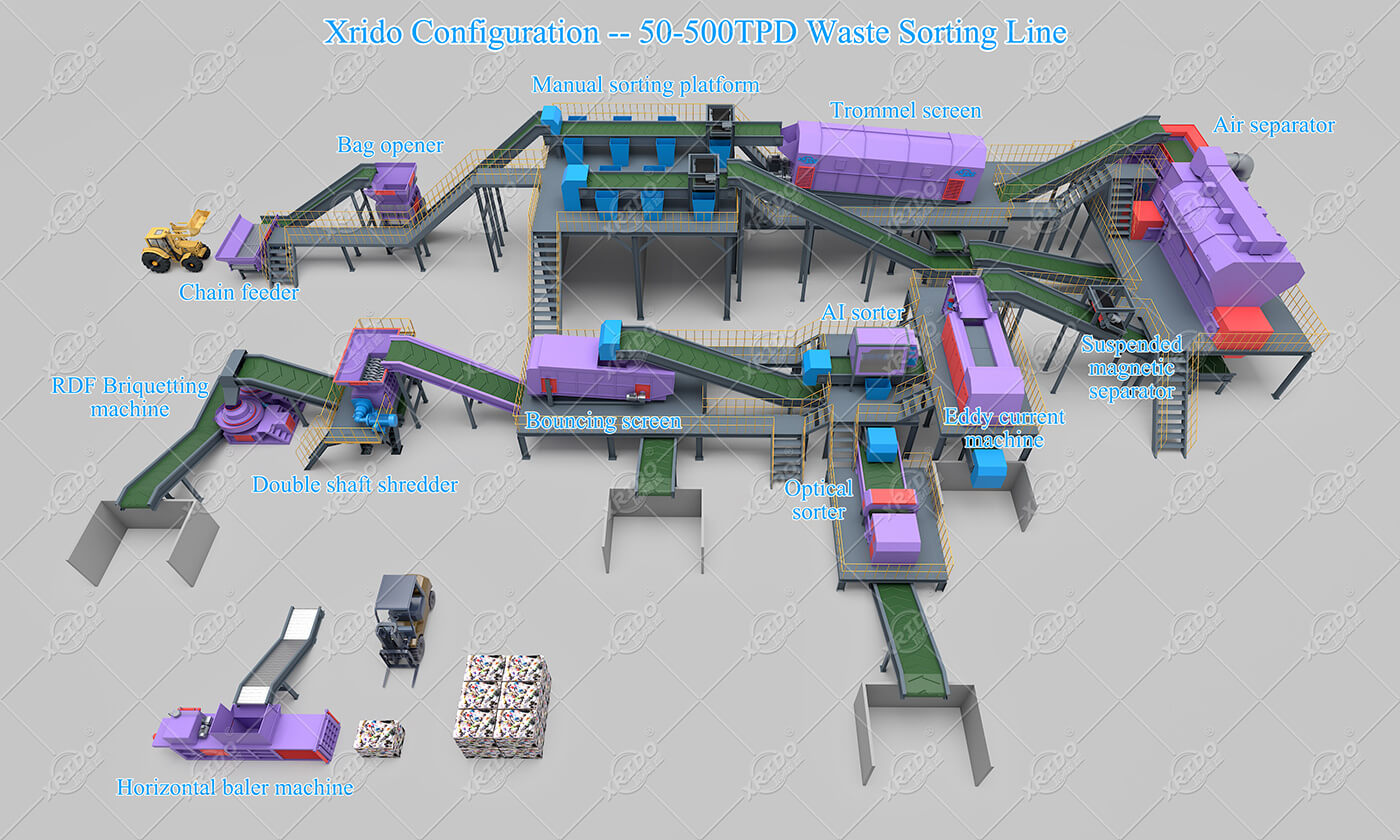

The production line can be customized based on actual materials and processing volume.

Wechat / WhatsApp: 86 1751317882

Specifically, the raw materials are input into the optical sorter equipment through a conveyor belt, and the spectral sensor is installed above the conveyor belt. When the material passes, the sensor can quickly scan the material on the conveyor belt, record and analyze the size, color and material of the material. If the identified material characteristic parameters are the same as the material characteristics set to be sorted, this information will be sent to the sorting unit of the optical sorter. The sorting unit sends a command signal to instruct the solenoid valve to release the pre-prepared high-pressure airflow. Under the action of the airflow (a large number of high-pressure nozzles), the specified material is blown away from the original drop track and taken away by the conveyor belt at the rear. The unseparated materials fall into the lower conveyor belt according to the original track.

Appliance

1. Plastic bottle related materials:

Complete plastic bottles: mineral water bottles (PET), beverage bottles (PET/PE), cooking oil barrels (HDPE), cosmetic bottles (PP), etc., sorted by material, color, and transparency.

Broken plastic flakes: Flake materials after plastic bottles are broken, remove impurities such as label paper, metal cap residues, glass fragments, and graded by material (such as PET flakes, PE flakes).

2. Cans and metal packaging:

Complete cans: aluminum cans (such as cola cans), iron cans (some beer cans), sorted by metal material, remove rusty and deformed cans.

Broken metal flakes: metal fragments after cans are broken, distinguish aluminum from iron (can be combined with magnetic separation technology), and remove non-metallic impurities such as plastic labels and dust.

3. Mixed recycled materials:

Plastic-metal mixed waste: such as a mixture of beverage bottles and metal caps, the sorting machine can identify the optical difference between the plastic bottle body and the metal cap to achieve automatic separation.

Recyclables in domestic waste: In waste sorting scenarios, identify and sort out recyclable packaging such as plastic bottles and cans to increase resource recovery rates.

Advantage

Video

Optical Sorter

The production line can be customized based on actual materials and processing volume.

Parameters

Can be customized

Color sorter used in msw sorting system