Shredding mattresses and recycling them into refuse-derived fuel (RDF) is a multi-step industrial process designed to separate and process the combustible materials in discarded mattresses, ultimately converting them into a high-calorific value fuel for energy recovery.We are an equipment manufacturer with a complete bulky waste sorting and recycling line. We can also customize production line equipment based on customer schedules.

Simplified Process Summary:

Waste Mattress

↓

Overall Shredding/Disassembly (Separation of Metal, Fabric, Foam, etc.)

↓

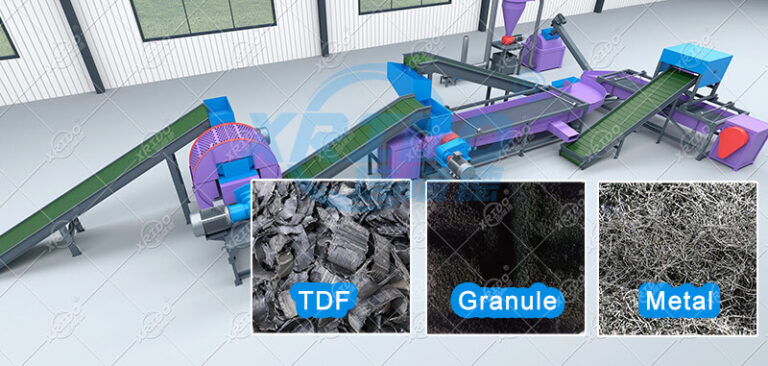

Fine Crushing → Sorting (Magnetic Separation, Air Separation, Gravity Separation)

↓

Extraction of Combustible Components (Fiber, Foam, Some Plastics)

↓

Drying/Crushing/Molding (Optional)

↓

RDF Production

↓

Energy Recovery (Cement Kilns, Power Plants, Incinerators, etc.)

Applicable Materials:

I. Mattress Shredding

- Whole-Body Pre-Shredding

If mattresses are not disassembled, they are fed directly into an industrial-grade shredder for coarse shredding, breaking the entire mattress into smaller pieces (typically 10-20 cm). - Fine Shredding

The shredded material is further processed through a fine crusher or hammer mill to break it into smaller particles (typically 2-10 cm, or even smaller, depending on RDF requirements). This increases the surface area for subsequent sorting and combustion.

II. Sorting and Purification

- Magnetic Separation

A magnetic separator removes ferrous metals (such as spring steel) from the shredded material, allowing these metals to be recycled separately. 2. Eddy Current Separation / Heavy Medium Separation (Eddy Current / Air Classification)

Removes residual non-ferrous metals (such as aluminum) and separates heavy and light materials to improve the purity of the combustible material.

- Air Classification / Trommel Screen

Based on material density and size, separates:

- Light combustible materials (such as polyurethane foam and textile fibers) → Used for RDF

- Heavy non-combustible materials (such as plastic shells, stones, and impurities) → Removed or processed separately

III. RDF Preparation

- Screening Combustible Components

After sorting, the main combustible components of a mattress include:

- Polyurethane foam (memory foam, sponge)

- Textile fibers (fabric, filling)

- Some plastics (such as polyester fiber, wrapping material)

These high-calorific value, flammable materials are selected as the raw materials for RDF.

- Mixing and Forming (Optional)

To facilitate storage, transportation, and combustion, some RDF production lines further process the combustibles:

- Drying (to reduce moisture and increase calorific value)

- Crushing to finer particles (<5mm-2cm)

- Compression/Pelletizing/Rolling (to form RDF pellets or RDF blocks, increasing density and combustion efficiency)

Note: Not all RDF requires forming. Some are used directly as a crushed fuel, known as "chipped RDF."

IV. RDF Utilization

The final RDF has a high calorific value (typically 14–20 MJ/kg) and can be used as:

- An alternative fuel for cement kilns (common and environmentally friendly)

- Auxiliary fuel for thermal power plants

- Fuel for industrial boilers

- Dedicated RDF incinerators

Compared to direct landfill or inefficient incineration, the energy utilization of RDF significantly increases the resource value of mattress waste while reducing environmental pollution.

V. Environmental Protection and Safety Control

- Waste Gas Treatment: The treatment process may generate dust and organic volatiles, requiring equipment such as bag filters and activated carbon adsorption.

- Odor Control: Organic materials such as sponges are prone to odor, so a closed system and deodorization equipment should be used if necessary.

- Compliance: The entire process must comply with local solid waste disposal and environmental regulations, particularly emission standards for dioxins, heavy metals, and hazardous gases.