Key Equipment for Material Handling in Cement Plants: Airbag Disposal and Textile Shredders

In the dual-goal advancement of "resource utilization + safe production" in cement plants, the standardized disposal of airbags and the efficient operation of textile shredders have become crucial links in improving material handling efficiency and mitigating safety risks. These two systems, respectively targeting special hazardous materials and flexible recyclable materials, utilize customized processing logics to adapt to the complex production environment of cement plants, providing assurance for raw material recycling and workshop safety.

Textile Shredding Machine for Air Bag

Textile Shredding Machine for Air Bag

Airbag disposal must strictly follow a three-step process of "explosion prevention - dismantling - resource utilization," adapting to the cement plant's control requirements for hazardous materials. First, the recovered waste airbags must be screened by specialized explosion-proof testing equipment. After confirming that the gas generator poses no risk of leakage, they are transferred to a closed dismantling station. Operators, wearing anti-static gear, use low-speed cutting tools to separate the airbag fabric from the gas generator. The gas generator must be collected separately and handed over to a qualified unit for harmless treatment to prevent it from exploding in the high-temperature environment of the cement plant. The separated nylon airbag fabric is then disinfected with ultraviolet light before being sent to the subsequent shredding stage. This entire process must be carried out in an explosion-proof workshop. The dismantling station is equipped with a dust concentration monitor and an emergency sprinkler system to ensure compliance with cement plant safety management standards. It can process 50-100 airbags at a time, with a fabric recovery rate of over 95%.

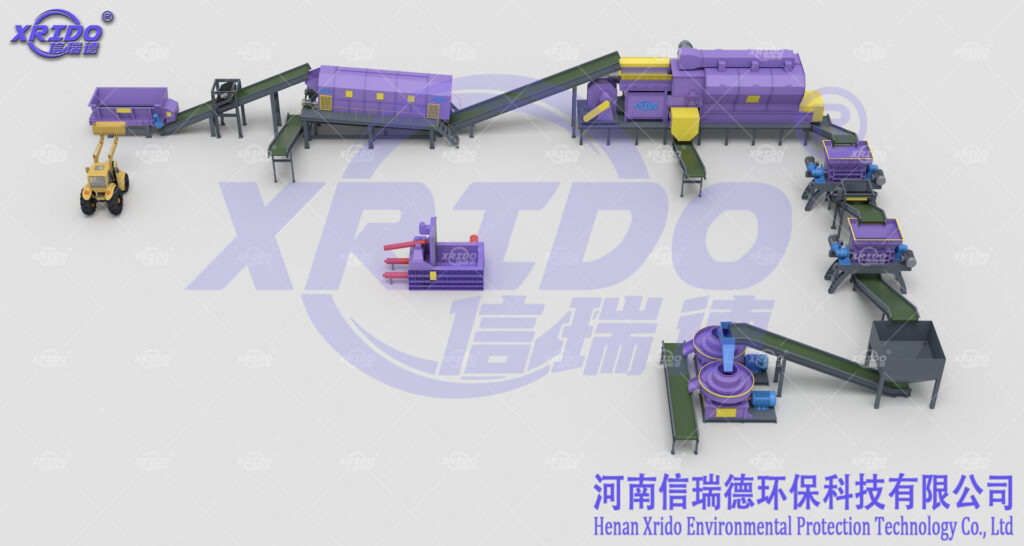

Textile Waste Disposal Plant

Bulky Waste Disposal Plant

The textile shredder, as a core piece of equipment for processing flexible waste in cement plants, is specifically designed for materials such as airbag fabric, waste filter bags, and packaging cloth. The equipment uses a dual-axis shearing blade assembly. The blades are made of SKD11 alloy material, which has been high-temperature quenched to a hardness of HRC60 or higher, effectively shredding textiles with a thickness of 5-20mm, avoiding the entanglement and jamming problems of traditional single-axis shredders. The feed inlet is equipped with an infrared sensor that automatically stops the machine when an operator's hand approaches, ensuring workshop safety. The output particle size can be controlled between 20-50mm by adjusting the blade gap. The shredded fabric fragments can be used as alternative fuel in a cement kiln for co-incineration or mixed with other waste materials to produce lightweight aggregate. A single unit can process 2-5 tons per hour, consuming only 60% of the energy of traditional crushers, and operating with noise levels below 85 decibels, meeting the environmental protection requirements of cement plant workshops.

In practical applications at cement plants, the two work synergistically: After the fabric from the dismantled airbags is shredded, 300-500 tons of solid waste can be reduced for landfilling annually. The use of alternative fuel can also reduce the cement plant's raw coal consumption by 8%-12%. Simultaneously, the standardized airbag handling process prevents gas generators from entering the raw material system and causing equipment malfunctions. After implementing this treatment solution, a medium-sized cement plant saw a 15% reduction in equipment downtime and annual maintenance cost savings exceeding 600,000 yuan. As cement plants upgrade their demands for resource utilization, optimizing the compatibility of airbag handling standards with textile shredders will become a key direction for improving material recycling efficiency and production safety.