The Importance of Material Recycling Facilities for Waste Management: Xrido Group Helps Upgrade Waste Management Plants

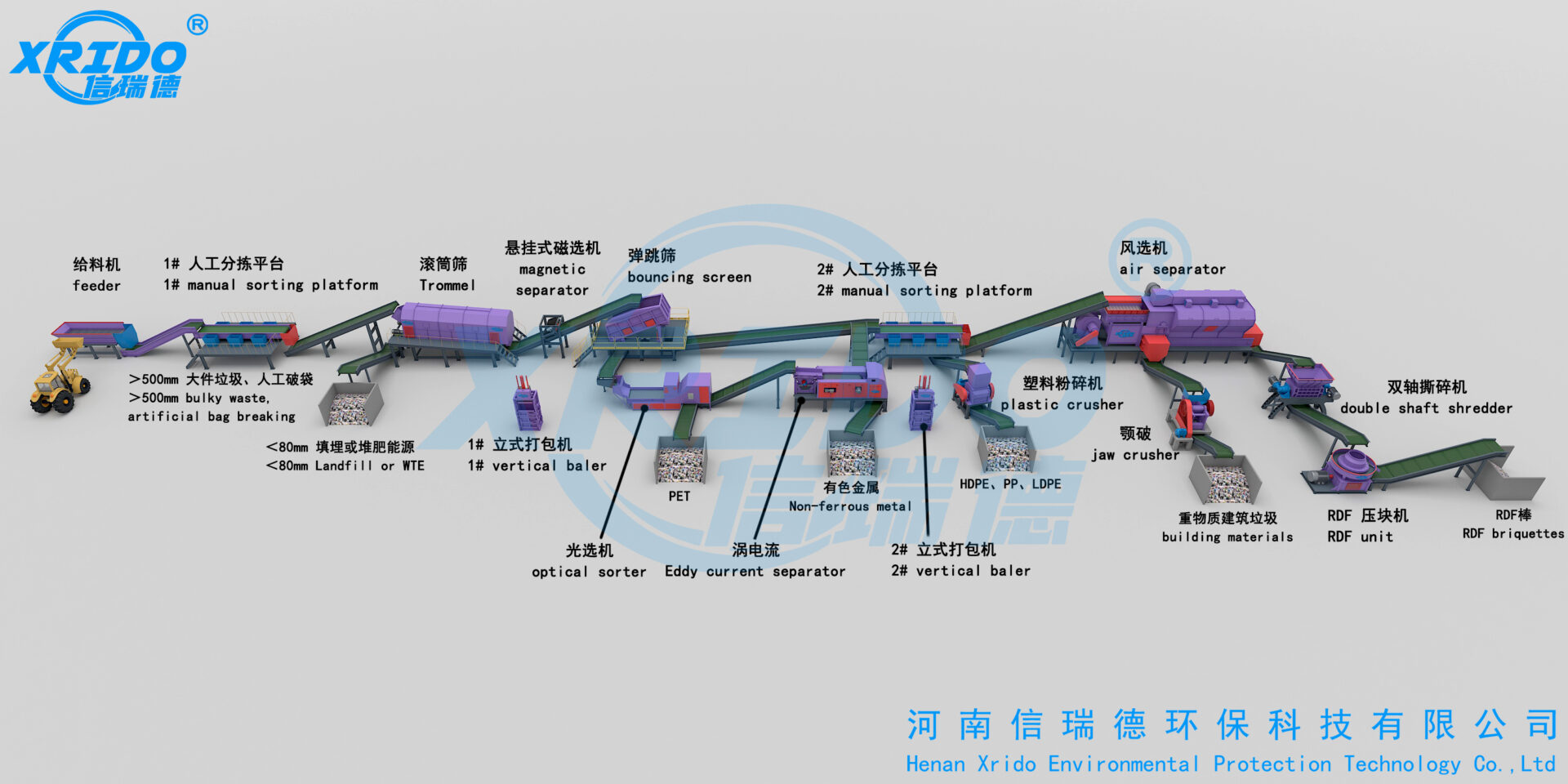

Driven by rising global environmental awareness and the "dual carbon" goal, waste management plants face multiple demands for "efficient processing, resource recycling, and environmental compliance." Material recycling facilities (MRFs), as a core component of the waste management system, are reshaping waste management models through professional processing. Xrido Group, with its customized equipment solutions, further amplifies the value of MRFs, providing crucial support for waste management plants to solve processing challenges and improve operational efficiency.

The primary value of MRFs for waste management lies in achieving "volume reduction," alleviating the processing pressure on waste management plants. In traditional waste management models, mixed waste often relies on landfill or incineration, which not only occupies land resources but also easily causes pollution problems. MRFs, through precise sorting, can separate more than 60% of recyclable resources (such as plastics, metals, and paper) from mixed waste, significantly reducing the amount of waste entering landfills or incinerators. For example, the material recycling facility built by Xrido Group for a waste management plant features intelligent sorting equipment that can increase waste volume reduction by up to 40%, reducing the plant's processing load by nearly 30% and significantly saving land and energy costs.

waste sorting plant. Recycling and sorting of household waste at the plant. Automatic sorting line

Waste sorting and recycling plant. Equipment for automatic waste sorting.

Secondly, the material recycling facility is key to promoting "resource recovery," creating economic value for waste management plants. Within the waste management system, the material recycling facility, through refined processing, transforms what was originally "waste" into standardized recycled raw materials—metal fragments can be directly used for smelting, and plastic granules can be reprocessed into products. These recycled materials bring additional revenue to the waste management plant. Xrido Group's integrated crushing and sorting equipment for the material recycling facility can increase the purity of recyclables to over 95%, increasing the plant's resource recovery revenue by 25%, achieving a "win-win situation for both environmental protection and economic benefits."

Furthermore, the material recycling facility can also help waste management plants achieve "environmental compliance" and reduce pollution risks. In traditional waste treatment processes, hazardous impurities (such as heavy metals and toxic chemicals) can easily spread with landfill leachate or incineration exhaust gases, causing environmental problems. However, material recycling facilities, using Xrido Group's specialized sorting equipment, can precisely separate hazardous waste for separate, harmless treatment. Simultaneously, the closed-loop processing reduces dust and odor emissions, allowing waste management plants to easily meet national environmental standards and avoid compliance risks.

For waste management plants, material recycling facilities are not only "transfer stations" in the treatment process but also "core engines" for improving waste management. By providing efficient and reliable equipment for material recycling facilities, Xrido Group further strengthens their role in waste management, helping waste management plants achieve the goals of "reduction, resource recovery, and harmlessness," and driving the entire waste management industry towards a greener and more efficient model.