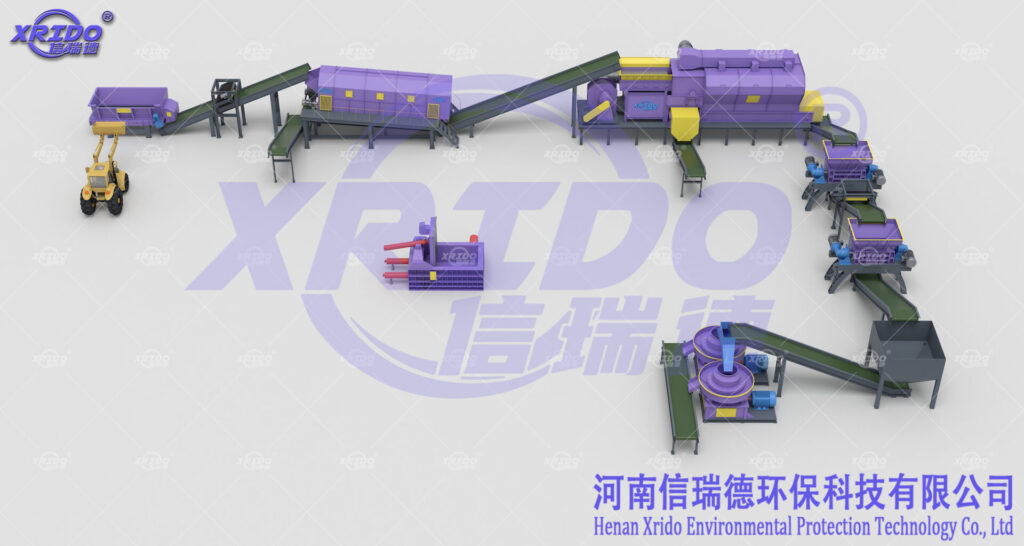

Waste Disposal Production Line: Core Equipment Facilitates Resource Recycling and RDF Conversion

With the increasing urgency for waste reduction, harmless treatment, and resource recovery, a highly efficient waste disposal production line has become crucial for solving the "garbage siege" problem. Core equipment such as drum screens, air separators, and dual shredders work in tandem to not only achieve precise waste sorting and reduction but also provide high-quality raw materials for the preparation of waste-derived fuel (RDF), driving the transformation of waste from "pollutants" to "energy carriers" and injecting strong momentum into environmental protection.

The drum screen, as the "first line of defense" in the waste disposal production line, undertakes the critical sorting task in the waste pretreatment stage. Its main body is an inclined cylindrical screen cylinder with screens of different aperture sizes covering the cylinder wall, allowing for grading and screening based on the particle size differences of waste components. When mixed waste enters the drum screen, as the screen cylinder slowly rotates, smaller inorganic particles (such as sand and gravel) fall through the screen into the collection device below, while larger organic particles, plastics, and paper are discharged from the end of the screen cylinder to enter the next processing stage. This pretreatment method effectively removes impurities from the waste, preventing subsequent equipment from having reduced service life due to wear from hard objects, and laying the foundation for subsequent precise sorting, significantly improving the processing efficiency of the entire production line.

The air separator, a "sorting expert" for separating light and heavy materials in waste, comes into play after the drum screen pretreatment. Utilizing aerodynamic principles, it generates a stable airflow through a fan. When the waste, after being screened by the drum screen, enters the air separator's sorting chamber, light materials (such as plastic film, paper, and foam) are blown towards the distant collection port by the airflow, while heavy materials (such as metal, glass, and large bricks) fall vertically to the heavy material collection area below due to their greater weight. The sorting accuracy of the air classifier directly affects the purity of the raw materials for subsequent RDF (Regenerative Thermal Disposal). By precisely adjusting parameters such as air velocity and air volume, lightweight combustibles in waste can be effectively separated, selecting the core raw materials for RDF preparation and reducing the impact of impurities on RDF combustion efficiency.

The configuration of two waste shredders is a core element in achieving "volume reduction + quality improvement" in waste disposal production lines and a crucial step in RDF preparation. Considering the complex composition of waste, a single shredder cannot handle diverse materials (such as large pieces of furniture, waste appliance casings, and thick plastic rolls). Therefore, production lines typically employ a "coarse shredding + fine shredding" operation mode with two shredders running in series. The first coarse shredder uses high-strength blades to break large, irregular pieces of waste into uniform materials with a particle size of approximately 10-20 cm, preventing material from clogging subsequent equipment. The second fine shredder further refines the material into particles with a particle size of 3-5 cm, increasing the specific surface area of the material and creating favorable conditions for subsequent RDF preparation processes such as drying and molding. The coordinated operation of the two shredders not only significantly reduces the volume of waste (volume reduction rate can reach over 70%), but also breaks down the internal structure of the material through the crushing process, improving the efficiency of subsequent pyrolysis and combustion treatments, and ensuring the stable quality of the RDF product.

One of the important outputs of the entire waste disposal production line is waste-derived fuel (RDF). After being screened for impurities, separated by an air classifier to extract lightweight combustibles, and crushed and refined by the dual shredders, the qualified waste material undergoes further drying and molding processes to ultimately produce RDF with a certain calorific value (typically 10-18 MJ/kg), low moisture content, and stable combustion. This fuel can be widely used in waste-to-energy plants, industrial boilers, and cement kiln co-processing, replacing some fossil fuels and achieving efficient utilization of waste for energy. Compared to directly incinerating raw waste, RDF has higher combustion efficiency and lower emissions of harmful gases (such as dioxins), not only reducing the environmental pressure of waste treatment but also providing a green option for energy structure transformation.

From the precise screening of the drum screen to the separation of light and heavy materials by the air classifier, and the efficient crushing by the dual shredder, the entire waste disposal production line, with its clearly defined division of labor and highly efficient collaborative equipment configuration, constructs a complete chain from waste collection to resource utilization. It not only solves the environmental problems caused by waste accumulation but also transforms "waste" into valuable resources through RDF conversion, providing a practical solution for sustainable development. With the continuous upgrading of environmental protection technologies, this type of production line will play an even more important role in promoting the construction of "zero-waste cities" and achieving "dual-carbon" goals.