Waste to Energy Plant : The Energy Conversion Journey of MSW to RDF/SRF

Hundreds of thousands of tons of solid waste (MSW) generated daily in cities are undergoing a remarkable transformation from "waste" to "fuel" thanks to the magic of waste-to-energy recycling systems. The MSW-to-RDF/SRF process is like a meticulously designed energy conversion pipeline, systematically releasing the energy hidden within the waste.

At the starting point of this "transformation pipeline," MSW, a mix of vegetable leaves, plastic bottles, and old newspapers, first enters the intelligent sorting workshop. Unlike traditional manual sorting, the infrared spectroscopy equipment here acts like a "sharp eye," identifying the material's composition and properties within 0.3 seconds. Working in conjunction with a high-speed robotic arm, it precisely removes non-combustible materials such as glass and metal. After this "screening" step, the remaining combustible materials resemble unpolished jade, stripped of impurities and ready for further refinement. Crushing is a crucial step in shaping the fuel. A specialized crusher acts like a precision "cutter," shearing the material into uniformly sized fragments. The standard 3 cm particle size ensures air permeability during combustion while preventing incomplete combustion caused by oversized particles. These fragments are then fed into a rotary drying drum. The 80°C hot air inside the drum is recovered from the system's own waste heat, reducing energy consumption while also lowering the moisture content of the material from over 50% to 8%, effectively drying out the fuel and significantly increasing its energy density.

MSW to RDF briquette Plant

Industrial Waste to SRF Plant

Biomass pellet/briquette Plant

Waste Tire Disposal System

In the final shaping stage, a briquetting machine compresses the dried material into 5 cm cubes—the final form of RDF/SRF. These black "energy blocks" have a stable calorific value of 16 MJ/kg, comparable to the combustion efficiency of high-quality lignite, yet cleaner than coal. At a European cement plant, these fuels are fed into high-temperature kilns, replacing 30% of coal consumption and reducing exhaust emissions by 30% due to efficient combustion. The process of converting MSW into RDF/SRF, from disorganized municipal waste to standardized green fuel, vividly illustrates how technological innovation can give waste new life. This system not only solves the problem of waste surrounding cities but also opens up a new energy source in today's energy shortages, demonstrating the infinite potential of recycling waste into valuable resources.

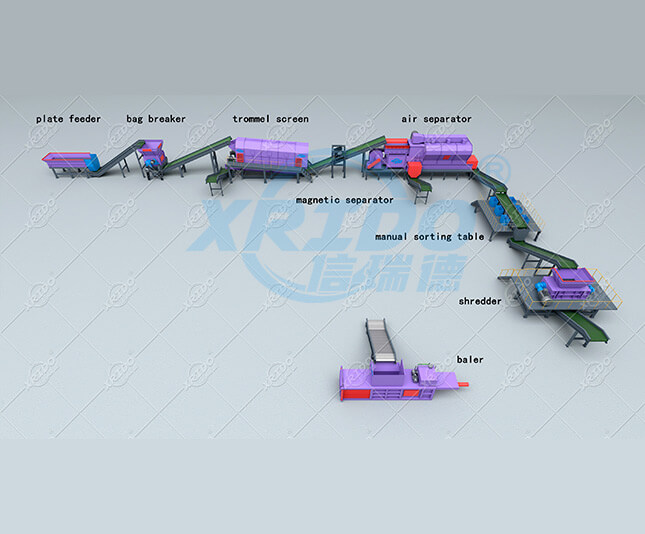

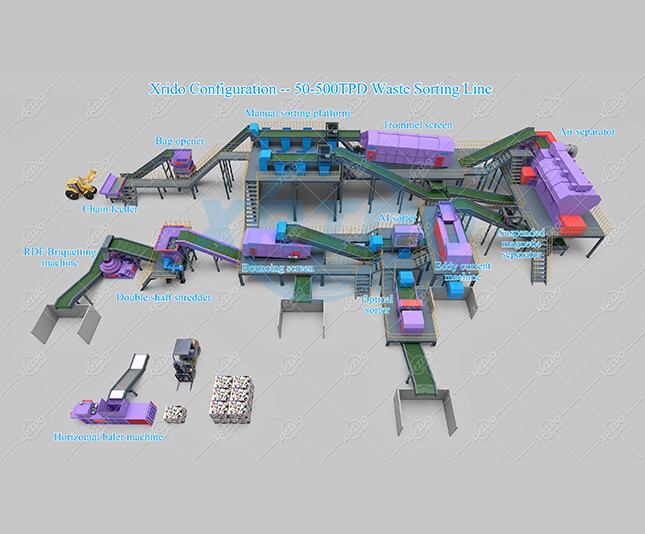

The process flow of municipal solid waste sorting equipment is as follows:

We are a manufacturer of garbage sorting and recycling equipment, which have been sold all over the world. Welcome to visit our factory in China.