What waste does a material recycling facility sort? Xrido Group's waste sorting machines enable precise classification.

As a core hub for resource recycling, the material recycling facility (MRF)'s core function is the precise sorting of mixed waste, separating recyclable resources from non-recyclable waste. The efficient execution of this process relies heavily on specialized waste sorting machines. Xrido Group, with its customized sorting equipment, enables material recycling facilities to cover various waste sorting scenarios, improving sorting efficiency while ensuring recycling purity, thus promoting the resource utilization of waste.

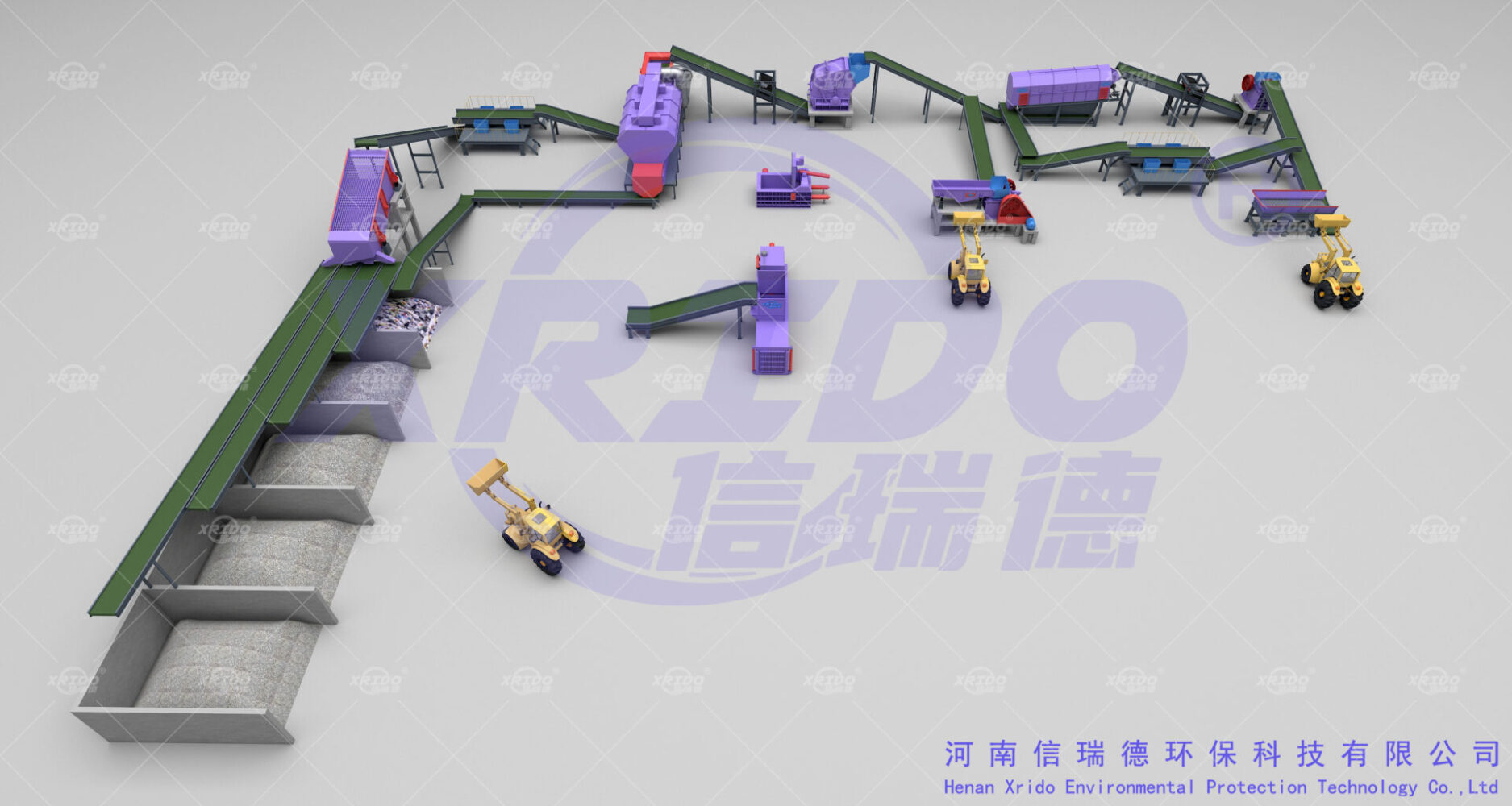

waste sorting plant. Recycling and sorting of household waste at the plant. Automatic sorting line

materials recovery facilities

The primary type of waste sorted by material recycling facilities is "metallic waste." This type of resource has high recycling value and is a key category in the sorting process. Commonly sortable metals include ferromagnetic metals (such as scrap nails, aluminum cans, and rebar ends) and non-ferrous metals (such as aluminum products, copper wires, and stainless steel scraps). In the waste sorting machines equipped by Xrido Group for its material recycling facilities, the high-gradient magnetic separation module can precisely adsorb ferromagnetic metals with a sorting efficiency of over 98%. The eddy current separator can separate non-ferrous metals through magnetic fields, efficiently extracting even tiny copper shavings less than 5mm in diameter, ensuring complete separation of metallic waste from mixed waste and providing high-quality raw materials for downstream smelting companies.

Secondly, "plastic and paper waste" is also a core sorting target for material recycling facilities. This type of waste accounts for over 30% of household waste and has significant recycling value. Sortable plastics include common categories such as polyethylene (PE) and polypropylene (PP), while paper waste includes waste cardboard boxes, newspapers, and packaging paper. Xrido Group's waste sorting machine utilizes a dual process of "air separation + screening" to precisely separate plastics and paper based on their density differences and particle size. The air separation unit separates lightweight paper and plastic from mixed waste, while the screening equipment further refines the materials according to particle size, preventing different materials from contaminating the recycling quality and increasing the purity of plastic and paper waste recycling to 95%.

trommel screen

optical sorter

In addition, the material recycling facility also sorts "glass and organic waste," further expanding the scope of resource recycling. Glass waste includes discarded glass bottles and glass fragments. Xrido Group's waste sorting machine uses a hardness sorting module to separate glass from other materials, preventing broken glass from scratching the equipment or mixing with other recycled materials. Organic waste (such as kitchen waste and plant residue) is separated using a dedicated screening device and can subsequently be converted into biomass fuel or organic fertilizer, achieving "turning waste into treasure."

From metals to plastics, from paper to glass, the sorting range of material recycling facilities covers a wide range of high-value wastes, and Xrido Group's waste sorting machines are the core guarantee for achieving precise sorting. They not only increase the sorting efficiency of material recycling facilities by 8 times compared to traditional manual methods, but also ensure the purity of recycled resources, laying the foundation for downstream recycling processes and truly enabling material recycling facilities to play a crucial role in resource recycling.