What is a Material Recycling Facility (MRF)? Xrido Group's Solid Waste Sorting Production Line Enables Efficient Recycling

In the resource recycling and environmental protection industry, a Material Recycling Facility (MRF) is a core hub for achieving "reduction, harmlessness, and resource recovery" of waste. Through specialized equipment and systematic processes, it classifies and purifies mixed waste, transforming recyclable resources into recycled raw materials. The solid waste sorting production line, as a core component of the MRF, directly determines its recycling efficiency and resource value. Xrido Group, leveraging its technological advantages, provides key equipment support for MRFs.

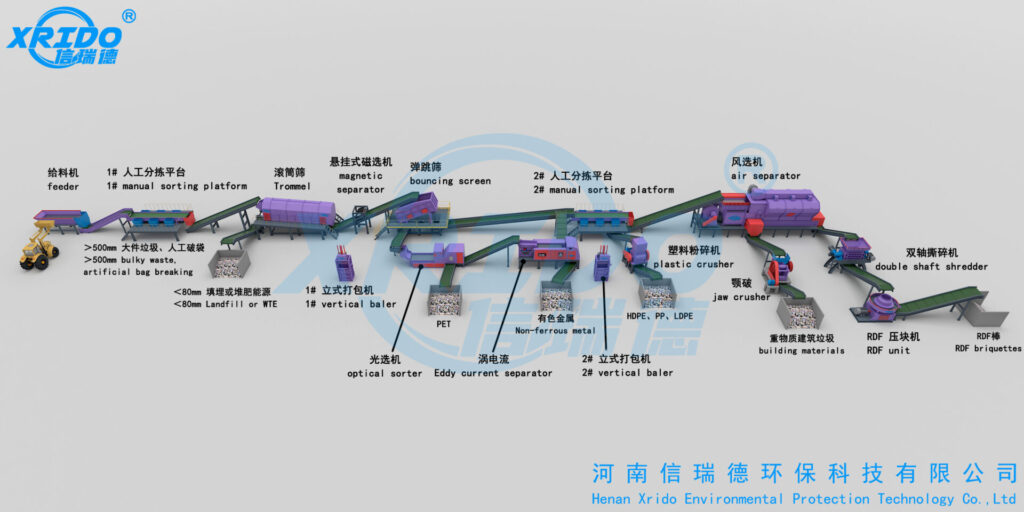

Simply put, a Material Recycling Facility (MRF) is a specialized facility for processing recyclable waste, not a traditional landfill. Its core function is to receive mixed waste from households and businesses, and through processes such as "pre-treatment - sorting - purification - packaging," separate recyclable materials such as plastics, paper, metals, and glass. After removing impurities, the waste is transported to downstream recycling companies to achieve resource recycling. For example, after municipal solid waste enters a recycling facility, large impurities (such as furniture and bricks) are first removed manually or mechanically. Then, it undergoes further fine sorting via a solid waste sorting production line, ultimately transforming the original "waste" into reusable industrial raw materials.

The solid waste sorting production line is the "heart" of a recycling facility's efficient operation, and Xrido Group's solid waste sorting production line, with its multi-process collaborative design, has become the preferred solution for recycling facilities. This production line integrates core technologies such as screening, magnetic separation, air separation, and eddy current separation: vibrating screening equipment separates waste of different particle sizes; high-gradient magnetic separators accurately extract ferromagnetic metals (such as iron nails and scrap steel); air separation devices separate light and heavy materials based on material density (such as paper and plastic); and eddy current separators efficiently separate non-ferrous metals (such as aluminum and copper). The entire production line operates fully automatically, avoiding the low efficiency and large errors of manual sorting, increasing the purity of recyclable materials in the recycling facility to over 95%, and improving processing efficiency by 3 times compared to traditional production lines.

Furthermore, Xrido Group's solid waste sorting production lines boast strong adaptability and energy-saving and environmentally friendly advantages. Their configuration can be flexibly adjusted according to the processing scale of the material recycling facility (100-1000 tons per day) and the type of recycled materials (municipal waste, industrial solid waste, and scrap materials), meeting the needs of MRFs of different scales. Simultaneously, the production lines utilize low-energy motors and a closed design, reducing energy consumption by 25% compared to the industry average. Dust and noise emissions meet national environmental standards, contributing to the green operation of material recycling facilities.

Driven by the "dual carbon" goals, material recycling facilities (MRFs) have become crucial infrastructure in the environmental protection industry. Xrido Group, through its professional solid waste sorting production lines, provides efficient and reliable equipment solutions for MRFs, helping them improve resource recovery efficiency and promoting the green and large-scale development of waste treatment, injecting key momentum into the construction of a resource recycling system.